Tofu sand case for cats

In Colombia

Tofu sand case for cats In Colombia

With the rise of the pet economy worldwide, Pet market demand demand, Especially the sands for cats, It is still increasing. Faced with the environmental protection trend, A Colombian pet company decided to introduce a new Tafu cattle sand line To meet the demand of the natural and biodegradable sand market.

What are the needs of the client?

To completely understand Customer needs, We organize a detailed online meeting in which the following points were discussed:

Production objectives: The customer expects to produce approximately 500 tons of sand for Tofu cats per month.

Product specifications: They have specific requirements regarding the size of the granules, The color and ability to absorb water, To satisfy local market preferences.

Environmental considerations: The client wants the production line to meet the environmental protection standards and reduce the emission of dust and wastewater.

Budget limitations: The client provided a clear budget range and hopes that we provide the best solution within the budget.

Plant conditions: Provided plans of the existing plant to facilitate our evaluation of the viability of the equipment installation.

What is our client solution?

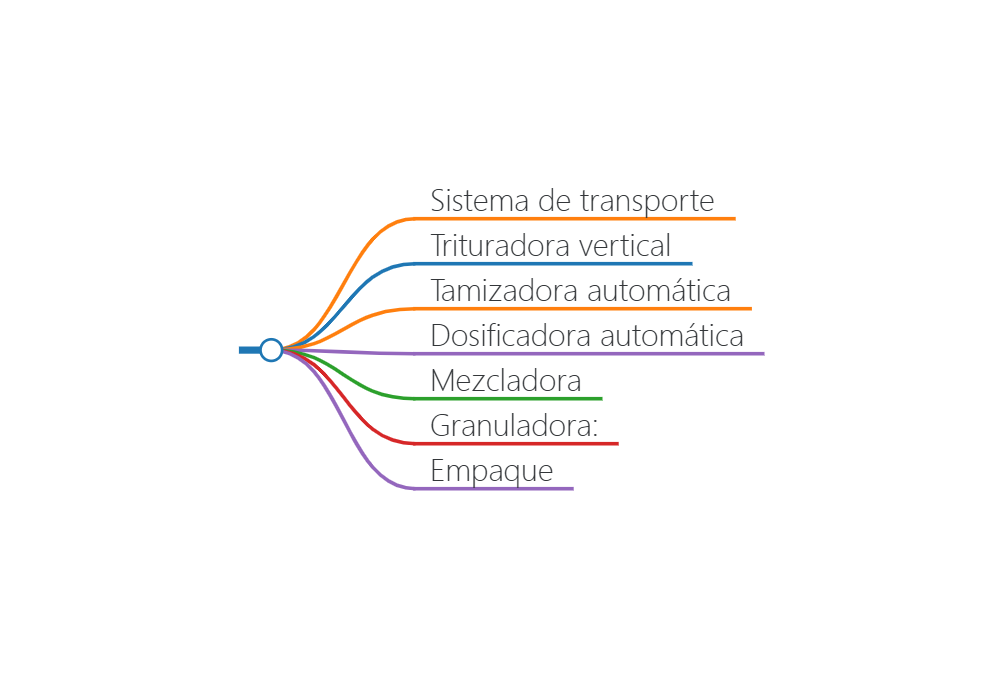

According to customer needs and plant conditions, Together with the professional experience of our technical team, We have designed a practical preliminary scheme to build a Tafu cattle sand line that is efficient and respectful of the environment.

1.Raw material treatment

2. Sieve and dosage

3. Mixing process

4. Granulation process

The raw materials of Tofu's sands will be introduced into the production process through a highly efficient conveyor belts system. The design of the conveyor belt ensures the stability and consistency of the materials during transportation, avoiding obstructions or waste.

Vertical crusher

Raw materials will be processed in a high efficiency vertical crusher, that can quickly crush Tofu residues into fine particles of uniform size, preparing them for sieve and later mixture.

Automatic sieve

The crushed material will be classified using an automatic sieve. This equipment can automatically separate particles of different sizes, ensuring that the processed materials are subsequently uniform and consistent, reducing quality fluctuations in production.

The automatic dosing

The qualified particles will be directed to the automatic dispenser for the precise mixture of ingredients. The dosing can automatically add several necessary additives, as deodorizers and antibacterial agents, according to proportions of pre -established formulas to improve product performance.

Double shaft mixer

Horizontal double axis mixer: Mixed materials will be introduced into a horizontal double axis mixer to achieve a homogeneous mixture. The unique mixer design ensures that, In a short time, The material is evenly distributed, preventing product instabilities due to an unequal mixture.

Granulator

Flat matrix granulator: The uniformly mixed material will be taken to the flat matrix granulator to form granules. The advantage of this equipment is that it does not require additional drying steps for granulation, Saving time and energy, and producing dense and uniform granules that meet market demand.

About details transport and delivery

1. Export preparations and customs

2. Shipping to the designated port

3. Online installation assistance

4.Continuous monitoring and support

After completing equipment production, We take care of managing all the necessary procedures related to export and customs formalities. This process included the preparation of all the required documentation, as commercial invoices, Packaging lists and origin certificates, To ensure that everything was in order for customs office. Our objective was to ensure a transition without problems from the facilities to the client, minimizing any possible delay or complication during international transportation.

Following customer specifications, We organize the sending of the team to the port indicated by them. During this process, We work in close collaboration with trusted and experienced transport agencies to ensure that the transfer by land and sea complied with the established deadlines and carried out safely.

Once the client received the equipment in the port and completed the transfer to its facilities, our engineers provided online assistance to guide the installation process. At the moment, All installation tasks have been successfully completed, And the client has started operating the equipment effectively.

We understand the importance of maintaining a close relationship with our customers even after delivery and equipment installation. Therefore, We carry out periodic follow -ups to verify that the team works according to expectations and to identify and solve any potential problem that may arise. This continuous communication not only strengthens our relationship with the client, but it also allows us to collect valuable comments to continue improving our products and services.

Get a Free Quote Now!

Get a free price within the 24 hours!