Flat matrix granulator press

Is there a granulation machine of organic fertilizers that does not require drying and is suitable for small -scale production?

The answer is yes! The flat matrix granulation machine It is an adequate option. Use rollers and matrices to extract and shape various organic materials after fermentation. It is not necessary to dry or crush the materials before granulation. You can process them directly in the form of cylinders without the need for prior drying.

What is your principle of operation?

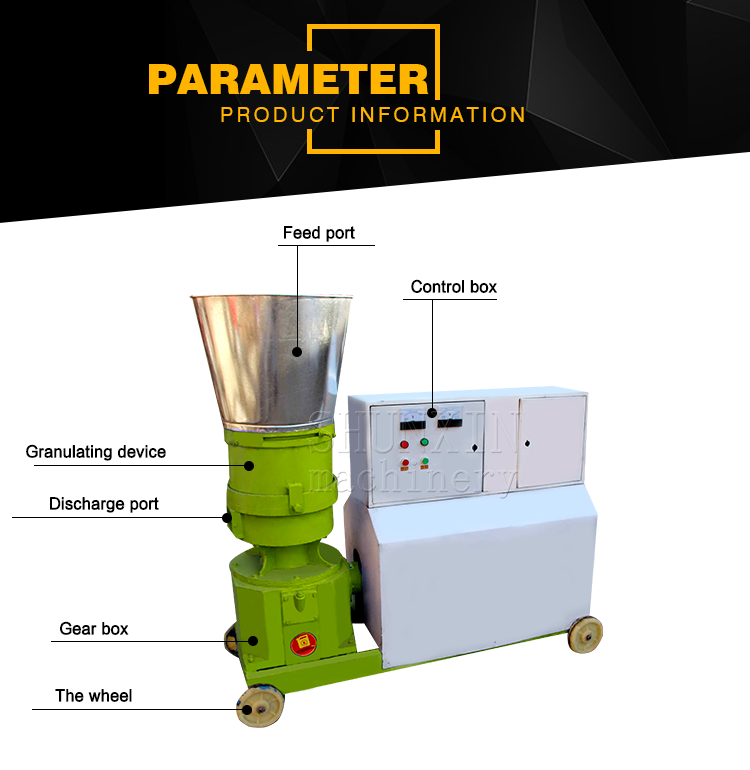

The granulating press machine with flat matrix is mainly composed of food hopper, Compression rollers, Matrix holes, gearbox, electric motor and frame structure. The electric motor transmits power through the gearbox, in turn, by gears, drives the rotation of the flat matrix or compression rollers, thus achieving the relative movement between the compression rollers and the flat matrix. This allows powdered material to be compressed and extruded through the matrix holes at the bottom of it. Just below the flat matrix, There is a low speed rotating blade that cuts cylindrical granules to the desired length. The flat matrix granulation machine It has a simple structure and great adaptability. The granules produced are uniform as a whole and have a regular form.

What are its main areas of application?

Flat matrix granulation machine is mainly used in the organic fertilizer pellet processing industry (biological) And in the livestock industry. It is especially suitable for granulation of materials of fiber gross, Like wooden chips, Rice peel, cotton stems, cotton seed shells, weeds and other crop residues. Pellets processed by the flat matrix granulation machine have a smooth surface and moderate hardness, which allows to better maintain internal nutrients of materials during the granulation process.

What are its advantages?

The granules have uniform composition and regular form, and the sizes of the granules of the granules can be φ2, Φ2.5, Φ3.5, Φ4, Φ5, Φ6, Φ7, Φ8, etc. Customers They can choose according to their production needs when ordering. Due to the low moisture content of the granules, They are easy to store and can maintain their original form during prolonged period in water. Significantly improves the use of materials. It is not necessary to dry before or after granulation, What considerably saves energy.

What is it for moisture requirements?

It is not necessary to dry the materials before granulation, But this does not mean that the presence of moisture is not allowed in them. The moisture content of the materials has a great impact on compression during the granulation process on the flat matrix machine. It is considered optimal that the humidity of the mixed materials is controlled between the 8% and the 10%. If the moisture content is too low, Materials will not adhere properly, what will result in granules with rough surface, Low resistance and low production, In addition to a greater load in the machine. On the other hand, A moisture content too high can cause the granules to deform, They are compacted excessively and even completely obstruct the granulation chamber. Therefore, It is important to carefully control the moisture of the materials before granulation.

How is your production capacity?

In behalf of other great teams, Its production capacity is small. We offer three models to choose: 1-1.5t/h, 1.5-2t/h, 2-2.5t/h. The size of the pellets is between 2-10mm.

What is your price?

The granulative prenza machine with flat matrix It is typical equipment used in dry composting granulation. It is very popular among small -scale fertilizer manufacturers. This is due to its low investment cost characteristics, Reduced space of space, Simple process and ease of operation. The price of a machine can range from 600 y 8,500 dollars.

What equipment is generally used with?

Because the materials produced do not require drying or cooling, Drying or cooling machines are not needed. Instead, It can be used The packing machine To directly package processed materials.

What to pay attention to during use?

During use, It is important to be careful to prevent materials from containing stones, iron pieces or other hard objects. Besides, When the machine is stopped for a long time, The waste in the components must be cleaned in a timely manner and perform an adequate anticorrosion treatment. It is also important to replace molds and rollers when they are worn.

Get a free price within the 24 hours!