The line of organic obonneas of chicken manure

Chicken manure is high quality organic fertilizer. It contains nutrients like nitrogen, match, potassium and other essential elements that provide full nutritional support for plants. However, Before using chicken manure as fertilizer, It is necessary to carry out a complete fermentation process.

Screws

Gallinaza fermentation

During the fermentation process, It is very important to regularly turn the manure. By turning, Channels are created to improve air circulation, which favors contact between oxygen and manure, providing an optimal respiratory environment for the growth and activity of beneficial microorganisms.

Through fermentation, harmful and parasitic microorganisms are eliminated, and organic matter decomposes in more stable and easily absorbable ways by plants, which promotes its growth.

If you want to manufacture the organic fertilizer production line powder, You just have to pack the organic fertilizer finished directly with the packer. If you want to manufacture gallinaza in granules, You must choose the appropriate granulater.

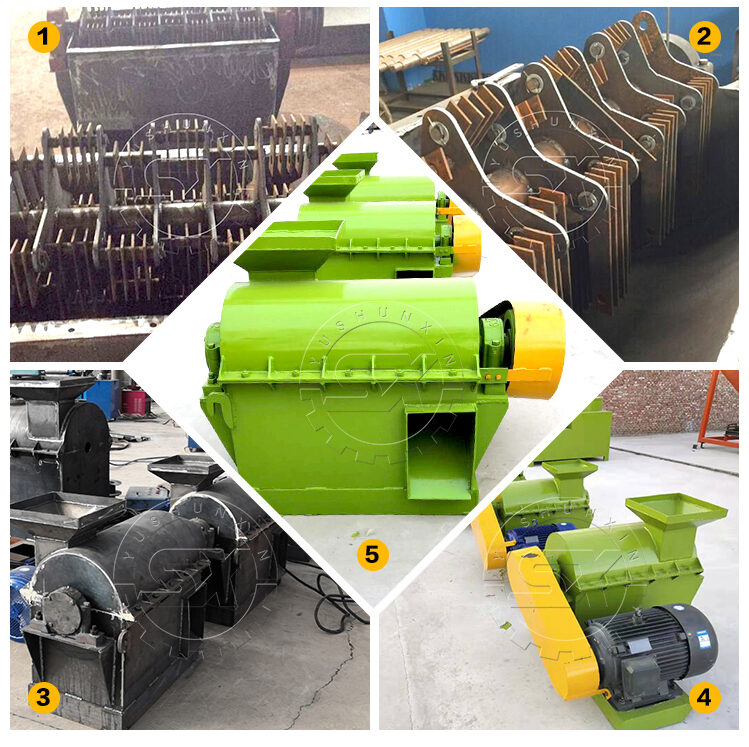

The roller compaction machine It is a very suitable option for the production of organic fertilizer granules from chicken manure. Has the following advantages:

In the end, You just need to use our automatic packing machine To package the granules. This machine can pack the granules quickly and efficiently, ensuring the ordered hermeticity and appearance of the product. You can configure the specifications and the weight of the packaging according to your needs, To meet market requirements and customers.

Get a free price within the 24 hours!