Sheep -up production teams in granules for 10t/h in Peru

We respond to the client's consultations in a timely manner, providing concrete improvement measures and recommending the type of equipment that would be more appropriate for your needs. We explain in detail how our products could help improve their production process and answer all their questions thoroughly.

The client was satisfied with the solution we offered and expressed his gratitude for our quick and professional response. As a result, has placed an order of our products, which demonstrates your confidence in the quality and effectiveness of our teams.

Here are the details of our communication on the real situation of our clients.

This is because the customer himself has experience in the production of organic fertilizer and some composting equipment. So they pay more attention to quality, Product production and efficiency capacity when selecting equipment.

Automatic dosing equipment

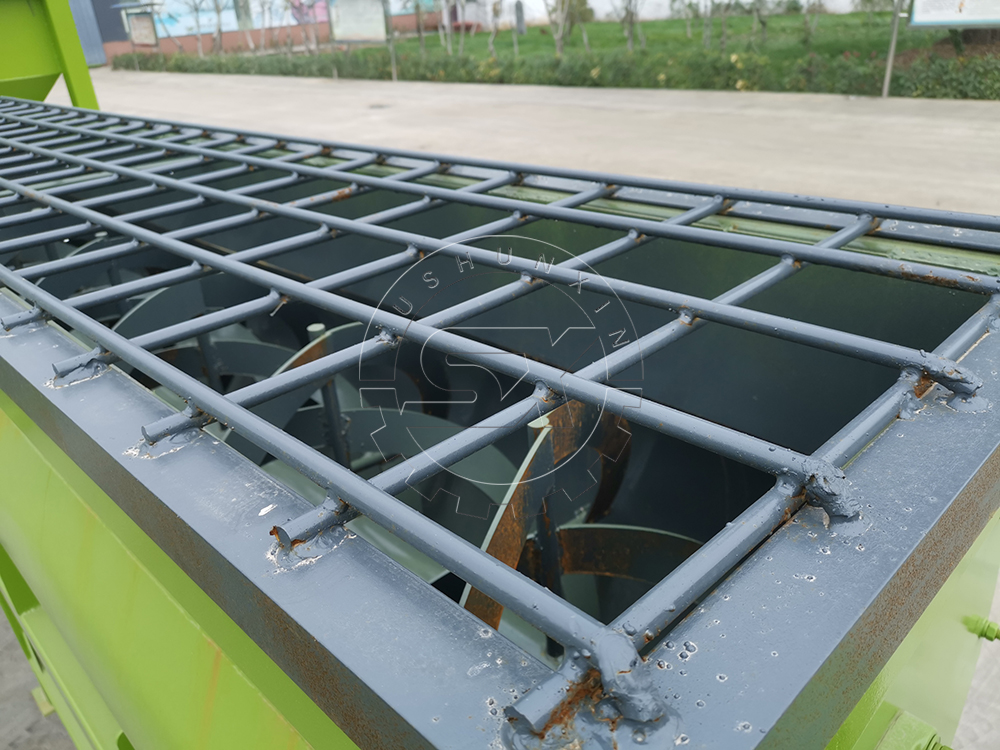

Mixing equipment

After the addition of supplementary materials, It is crucial that these are mixed uniformly to guarantee a final good quality product. Our double axis mixer has the ability to perform this task efficiently. Thanks to its innovative design, You can mix a variety of materials in a homogeneous way, ensuring that they are distributed evenly throughout the lot. This allows each part of the fertilizer lot to have the same concentration of nutrients, thus improving product efficacy. Besides, Our double axis mixer is easy to operate and maintain, and is built to withstand the wear of constant production, which makes it a lasting and reliable option for the production of organic fertilizers.

Sheep -up production teams in granules

The next step in the production of organic fertilizers is the granulation process. For which we recommend our clients Our double roller compaction grainulator. This equipment is especially suitable for customers with high granulation production, since four sets of this team can be combined to handle the demand.

Hoppers for accent

We also offer storage hoppers as part of our product catalog. These hoppers are fundamental in the production process, since they allow the safe and efficient storage of the materials before and after dosing, mixture and granulation.

Our storage hoppers are designed to handle a wide range of materials, offering sufficient storage capacity to maintain the efficiency of the production process. Besides, They are built with durable materials to resist the most demanding working conditions(For example, Resistance to corrosion).

The design of our hoppers also facilitates the loading and discharge of materials, minimizing the time and effort necessary for these tasks. Our storage hoppers contribute to optimizing the production of organic fertilizers of our customers.

Heavy and embolized equipment

Our automatic packaging scale is designed to handle both the weighing and the packing of the products quickly and accurately. The weighing equipment guarantees that each bag contains the exact amount of product, improving efficiency. This equipment automates the filling and sealing process of the bags, resulting in a faster and more efficient embolism, reducing production time and optimizing labor.

At this point, We have covered all organic fertilizer production processes and the equipment we offer to optimize each of them. From the precise dosing of the materials, The uniform mixture, efficient granulation, Safe storage until precise weighing and embolism, Our equipment solutions are designed to increase the efficiency and competitiveness of our clients in the organic fertilizer market.

We hope this information is useful for our customers. We are at your disposal to answer any questions or provide more details about our products and services. Our goal is to help our customers achieve their production goals in the most efficient and profitable way possible.

Get a free price within the 24 hours!