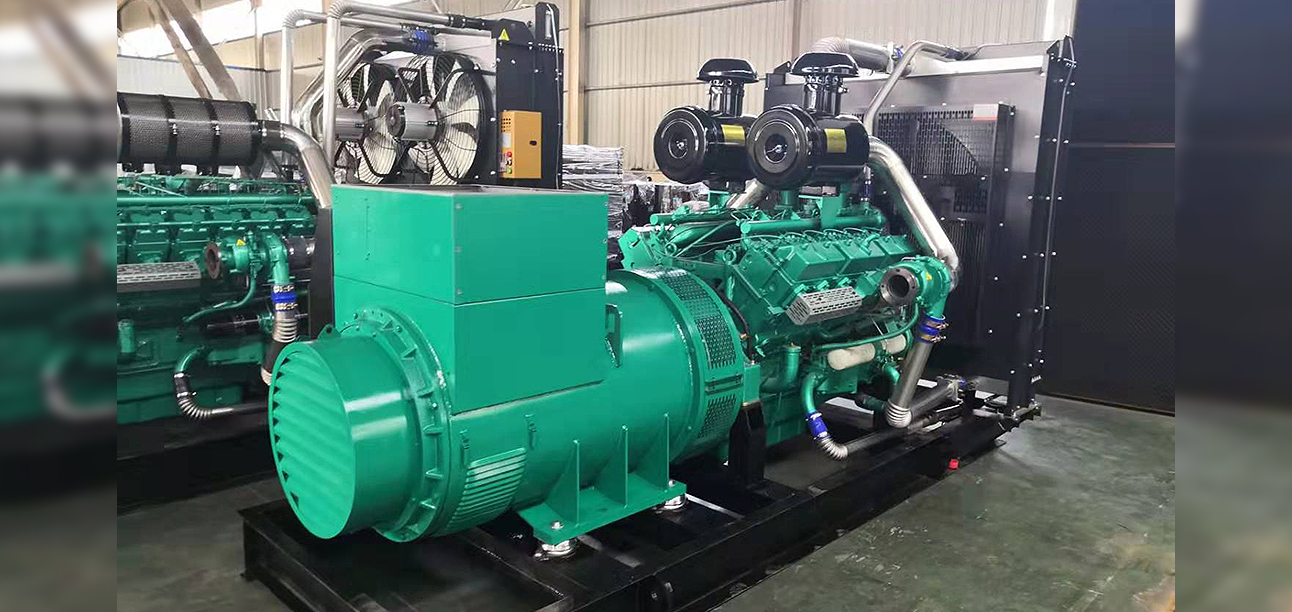

Generator

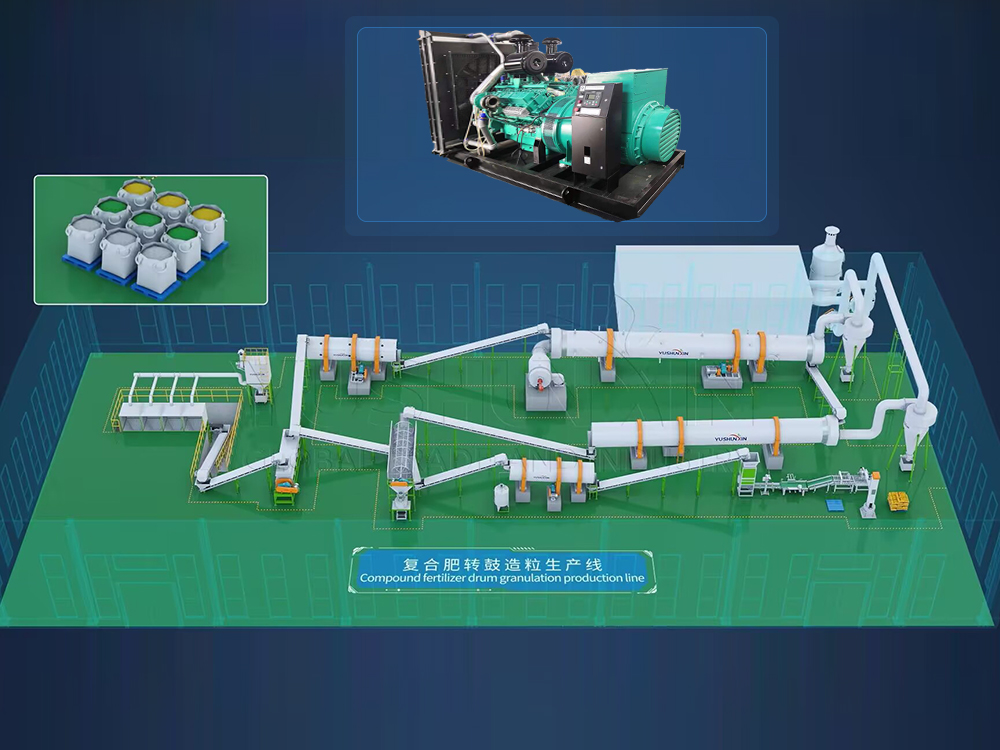

for organic fertilizer production line

Solutions for the production of organic fertilizers with a shortage of electrical resources

In regions where energy resources are scarce, organic fertilizer production often faces the challenge of insufficient electricity supply. To solve this problem, we can offer organic fertilizer granulation companies an innovative solution: a comprehensive system that combines production lines with generating sets, as well as the configuration of generator sets for individual equipment.

In summary—by offering a solution of production lines plus generator sets, as well as the configuration of generator sets for individual equipment, We can provide effective support to organic fertilizer production companies in areas with scarce energy resources., helping them achieve stable and efficient production in difficult environments.