In Spain

The Atapulgita granulation project

The Atapulgita granulation project In Spain

The atapulgated, Also known as Palygorskita, It is a clay mineral with exceptional absorbent and rheological properties, What makes it useful In several industrial applications, From oil absorbents to additives in the drilling of oil wells. In the Castilla-La Mancha region, Space, An important site of this mineral has been the object of exploitation by a local mining company. The need to improve the efficiency of Atapulgita processing led to the search for innovative granulation solutions.

What granulation solution was implemented for Atapulgita?

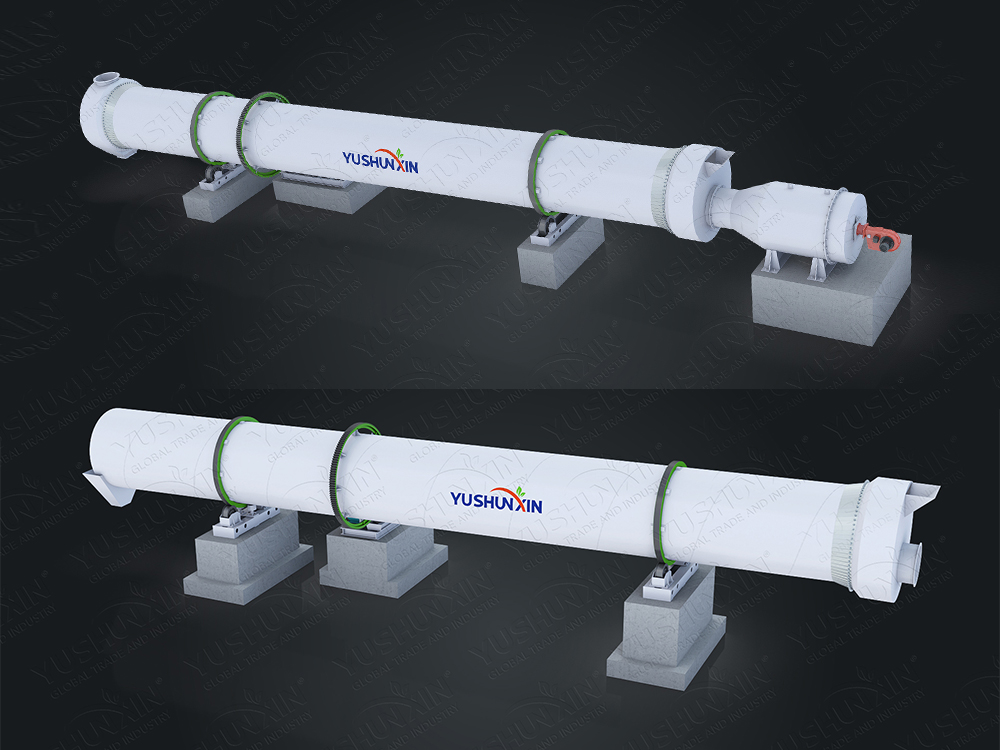

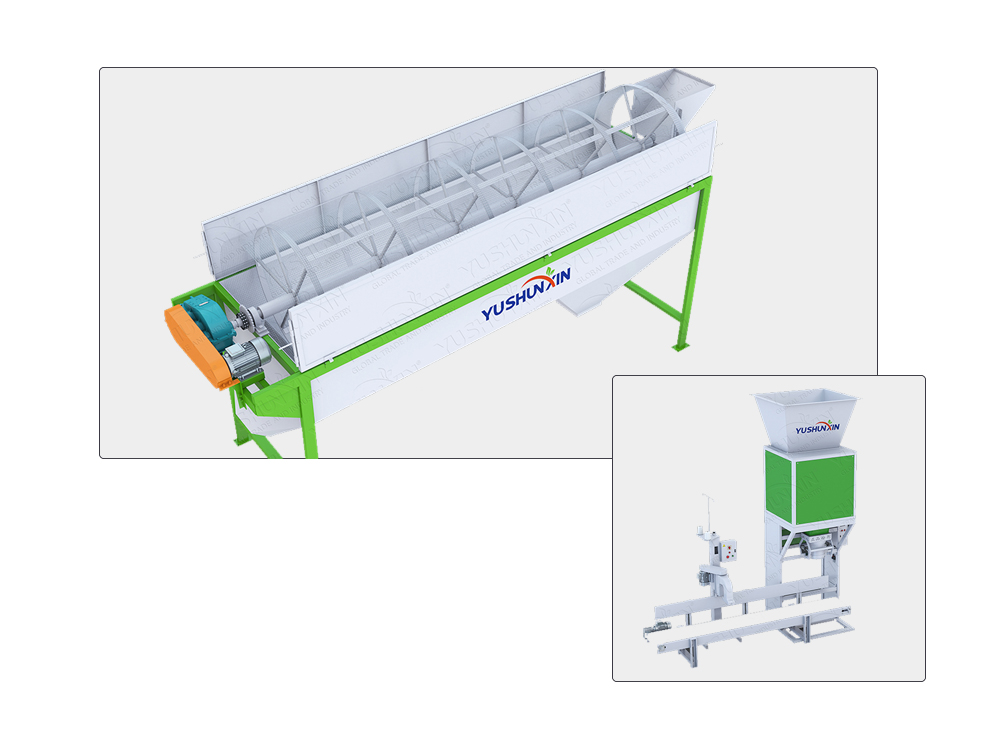

To address these needs, The implementation of an advanced Atapulgite granulation solution was proposed. This solution consisted of the use of a wet granulation system, which uses mechanical action and specific binders to form consistent granules. This method not only improves the manageability of the material, It also increases its stability during transport and storage.

Get a free price within the 24 hours!