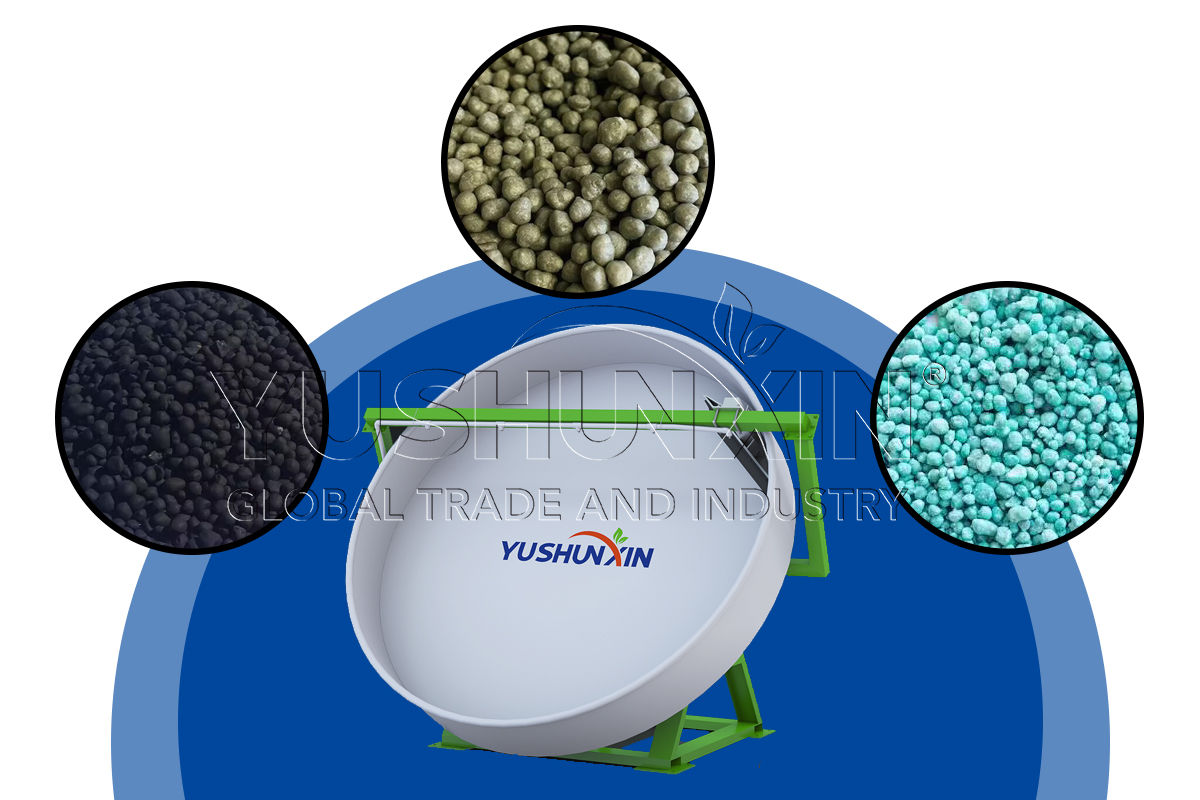

Disco granulator

Compared to powdered fertilizers, Organic fertilizer granules have great advantages in transport and storage. So, How is organic fertilizer powdered to turn it into granules? To meet fertilizer granulation requirements, We have designed several granulation machines for you to choose. One of them is The disc granulation machine.

How does pellets?

The principal principle of disc granulation machine is the following: The main engine drives the pulley and strap through a speed reduction transmission system, The small gear is coupled with the large fixed gear at the bottom of the disc, and work in the opposite direction. The big gear is installed on the main axis, which is fixed on the adjustment disc mounted on the frame, To support the work of granulation disc (This machine is used in combination with a sprayer). After the materials enter the granulation album, through the continuous rotation of the disc and the spray device, The materials adhere and agglutinate to form granules in the form of a sphere. At the top of the granulation album, An automatic cleaning device has been designed to prevent materials from adhere to the wall, which considerably improves the life of the machine. With the continuous rotation of the engine, The constant feeding of the materials allows a large -scale production that meets the user's needs.

What is a general structure?

The part of the machine frame is made of Carbon steel High quality welded in the form of a channel. The structure of the granulation disk has a comprehensive circular arc shape, which allows to reach the higher granululous formation rate to the 95%. The granulation disc bottom is reinforced with multiple radiated steel plates, What makes it resistant and durable, Without deforming.

The base design is thicker, reinforced and resistant, It does not require anchoring bolts to the ground and provides stable operation. The main gear of the granulation machine uses the high frequency tempering process, which increases its useful life in a 100%. The interior coating of the granulation disc is made of fiberglass high resistance, which makes it resistant to corrosion and durable. The adjustment part is made of high quality carbon steel plates and welded channel section. It is precisely the special treatment of each component that guarantees the general performance of the machine.

What material can be processed with it?

The album granula, also known as The universal granulation machine. This is called due to its wide range of applications. This machine is especially suitable for the granulation of light and fine material materials. The finerst the basic particles of powdered materials, greater will be the sphericity of the granules and it will better be their spherical quality. Typical materials for application include cow manure granulation, sheep, Chicken and pork. As well as the granulation of materials such as metallurgy, bentonite, Limestone, coal schistles, inter alia.

What are its advantages?

- 1

Investment savings: Production with disc granula can save up to a 30% compared to other composite fertilizer production technologies.

- 2

Wide adaptability: The disc granulation machine has wide adaptability to different types of materials.

- 3

Easy operation: The disc granulation machine is easy to operate, With flexible control and adjustment.

- 4

Low production cost and high profitability: Production with disc granulation machine offers lower production costs and high economic benefits.

What other equipment is needed for the complete disc granulation line ?

If you want to produce high quality organic fertilizer, A single granulation machine is not enough. It is necessary to combine it with other equipment. The complete organic fertilizer production line includes: Material crusher, Automated dosing machine, disc mixer, Disco granulation machine, dryer, cooler, screening machine, Chain crusher, coating machine and automatic packing scale. These equipment will allow you to achieve continuous production of organic fertilizer granules.

How much does album granulatora cost and how the teams choose?

There are several models of the album granula, each with different production parameters, size and other aspects. It is also reflected in prices. When buying equipment, It is important to choose the right model. It is recommended to opt for manufacturers that sell directly, since it is usually more profitable than through distributors. Besides, It is advisable to choose manufacturers with solid trajectory. Since your system is usually more complete and provide a comprehensive service, What helps avoid many problems.

Technical Parameters of the Disco Granulator

| Model | Is. of Disc (mm) | Edge Height (mm) | Rotary Speed (r/min) | Motor Power (kw) | Capacity (t/h) | Reducer Model | Dimensions (mm) |

|---|---|---|---|---|---|---|---|

| SXYZ-500 | 500 | 200 | 32 | 0.55 | 0.02-0.05 | Byw043-0.55 | 650×600×800 |

| SXYZ-600 | 600 | 280 | 33.5 | 0.75 | 0.05-0.1 | Byw043-0.55 | 800×700×950 |

| SXYZ-800 | 800 | 200 | 21 | 1.5 | 0.1-0.2 | XWD4-71-1.5 | 900×1000×1100 |

| SXYZ-1000 | 1000 | 250 | 21 | 1.5 | 0.2-0.3 | XWD4-71-1.5 | 1200×950×1300 |

| SXYZ-1200 | 1200 | 250 | 21 | 1.5 | 0.3-0.5 | XWD4-71-1.5 | 1200×1470×1700 |

| SXYZ-1500 | 1500 | 300 | 21 | 3 | 0.5-0.8 | XWD5-71-3 | 1760×1500×1950 |

| SXYZ-1800 | 1800 | 300 | 21 | 3 | 0.8-1.2 | XWD5-71-3 | 2060×1700×2130 |

| SXYZ-2000 | 2000 | 350 | 21 | 4 | 1.2-1.5 | XWD5-71-4 | 2260×1650×2250 |

| SXYZ-2500 | 2500 | 450 | 14 | 7.5 | 1.5-2.0 | ZQ350 | 2900×2000×2750 |

| SXYZ-2800 | 2800 | 450 | 14 | 11 | 2-3 | ZQ350 | 3200×2200×3000 |

| SXYZ-3000 | 3000 | 450 | 14 | 11 | 2-4 | ZQ350 | 3400×2400×3100 |

| SXYZ-3600 | 3600 | 450 | 13 | 18.5 | 4-6 | ZQ400 | 4100×2900×3800 |

Get a free price within the 24 hours!