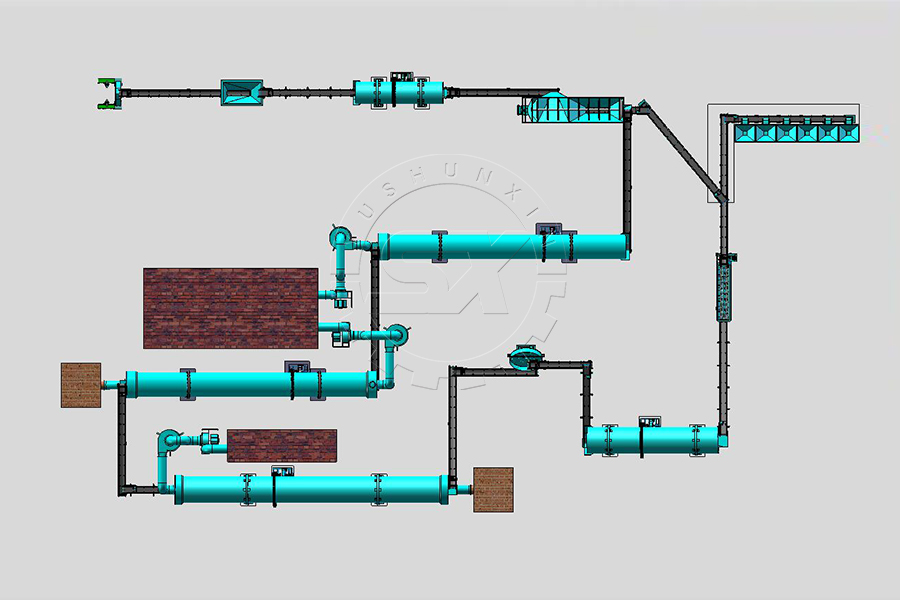

Large -scale organic fertilizer granulation production line

When you are considering large -scale production of granulated organic fertilizers, You must take into account these four aspects: ensure stable supply of raw materials, Choose team reliable supplier, Packaging and storage of the final product, as well as construction costs and expenses.

How to ensure stable supply of raw materials?

Guarantee.

Searching and establishing long -term cooperation relationships with reliable suppliers is key to guaranteeing stable material supply. Select suppliers with good reputation and stable supply capacity, Like great breeding farm.

Depending on a single supplier can lead to risks, therefore, It is recommended to establish a material acquisition network through multiple channels. This reduces the risk of supply interruption and provides alternatives in case of problems with some suppliers.

How to choose the large -scale production equipment of organic fertilizers?

The production capacity of organic fertilizers is crucial. So, What equipment does you need to buy for the production of large -scale organic fertilizers? You can choose between the following equipment for organic fertilizers.

Wheel compost

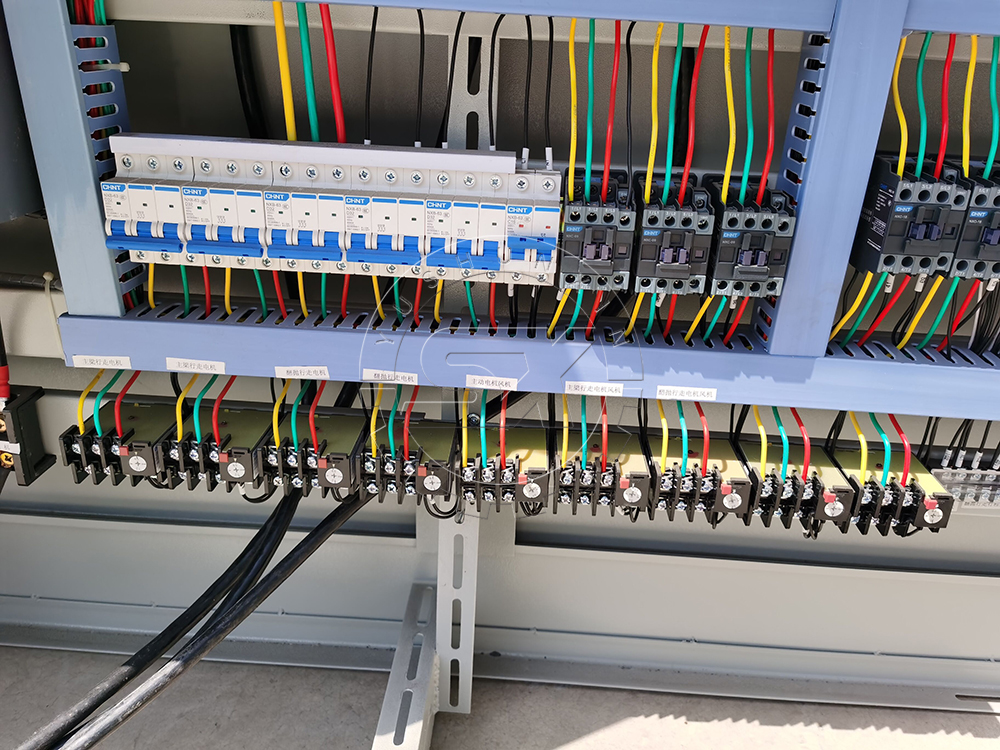

The wheel turning machine is suitable for fermentation and turning of large organic waste, High depth. Compared to traditional voltage equipment, Its depth of voltage can reach 1,5-3 meters and its flip width can reach 30 metros. Use a unique and efficient transmission mechanism in energy, which reduces energy consumption in a 70% compared to traditional voltage devices with the same amount of work. The symmetric wheel flip guarantees a uniform distribution of the material and uses an adjustable speed displacement car to achieve flip without dead angles. Through a fully automated electrical control system, No manual operation is required during equipment operation, which increases process automation.

Crushing machine

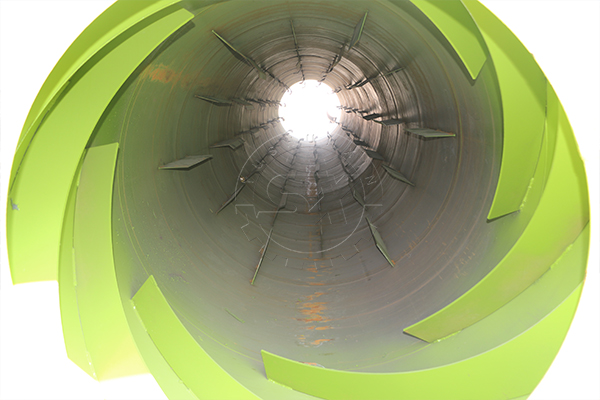

For large -scale crushing of organic fertilizers, The new vertical crusher It is adequate option. Its maximum capacity is 15 tons per hour and the input size is 650 × 450 millimeters. Besides, The machine adapts very well to organic waste with high water content thanks to its great capacity. By processing large amounts of animal manure, It is not easy to get stuck and the download is soft.

How many cost of the production of large amounts of granulated organic fertilizer?

- Construction costs and expenses

Before starting the construction of the production plant, It is important to evaluate the associated costs and expenses.

The large -scale organic fertilizer granulation production line, with capacity of 10-20t/h, including all the aforementioned teams, It has approximate total cost of between 360,000 y 550,000 US dollars. When performing specific project planning, It is recommended to discuss and negotiate in detail with relevant suppliers and professionals to obtain a precise cost estimate.

Get a free price within the 24 hours!