Customized production solution

for an organic mineral fertilizer manufacturer in Colombia

In Colombia, The agricultural sector has been looking for ways of sustainable production to meet the growing market demand, while maintaining soil health and productive efficiency. As a manufacturer of organic mineral fertilizers, One of the challenges the customer faces in their production process is how to reduce dependence on rotary dryers and improve granule quality., especially with the requirement that the granules be completely spherical. Double roller pelletizing machine has become a key customer interest equipment. This article provides an optimized solution based on customer needs, helping you improve production efficiency, reduce energy consumption and ensure high quality of granules.

Packages Delivered

Warehouse Facilities

Happy Clients Worldwide

Summary of customer needs

As a manufacturer of organic mineral fertilizers in Colombia, the client seeks to optimize the production line, reduce the frequency of use of rotary dryer and meet strict requirement: the granules must be completely spherical. Besides, The customer has shown great interest in double roller pelletizing machines, especially in the urea handling process (Urea), DAP (diammonium phosphate), KCl (potassium chloride) and organic fertilizers, with the aim of increasing production efficiency, reduce energy consumption and ensure granules are uniform and of high quality.

Solution: Optimization of production line configuration

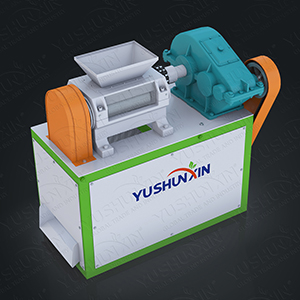

In the traditional production process, rotary dryer is used to remove moisture from materials, but relying too much on this equipment not only consumes a lot of energy, but also increases maintenance costs. To effectively reduce the use of rotary dryer and improve production line efficiency, double roller pelletizing machine is the most suitable option for this purpose.

Efficient granule formation:

The double roller pelletizing machine uses the pressure of two rollers to compact the material and form uniform, spherical granules.. Compared to disc pelletizing machines, those with double roller achieve a more precise formation of the granules, which meets customer's requirements for granule shape.

High Adaptability:

The double roller pelletizing machine is not only suitable for treating traditional materials such as urea, DAP y KCl, but is also compatible with the production of organic fertilizers. Customer's organic mineral fertilizer mixture can form uniform and regular granules by this equipment, improving the quality of compound fertilizer.

Comprehensive solution for an efficient production line

According to customer needs, The following is the customized production line configuration:.

Premix system

In the production process, An efficient mixer will first be used to evenly combine the fertilizers such as urea, DAP, KCl and organic substances. This step is crucial to ensure the quality of the granules, since effective mixing ensures uniform distribution of fertilizer components, avoiding irregular applications.

Double Roller Pelletizing Machine

After mixing, Double roller pelletizing machine will be used to compress and form the granules. This equipment ensures that the mixture becomes spherical granules, with the same density and size, meeting strict customer requirements.

Automatic sieve

Through a drum sifter, granules are classified according to their size. This screening process ensures that only granules that meet quality standards make it to the next stage., while non-conforming granules are returned for reprocessing. This step improves the consistency of the quality of the final product.

Automatic packaging system

The sifted particles are transported to an automatic packaging machine for measurement and packaging.. According to customer needs, Bags of different specifications can be selected and the production date and batch number are automatically printed to ensure product traceability.

Sustainability and energy efficiency

In the production process, The client can also improve sustainability and energy efficiency through the following strategies:

Through these technological improvements and the updating of equipment, the client will be able to reduce the use of rotary dryers and improve the precision in granule formation, ensuring that these are completely spherical. Double Roller Pelletizing Machine, with its ability to improve the quality and uniformity of granules, will help the client increase production efficiency and competitiveness in the market. Besides, The line will allow reducing energy consumption and optimizing the production process, achieving sustainable goals. With this optimized production solution, the client will be able to satisfy the growing demand for high quality organic mineral fertilizers in the Colombian market, and remain competitive in this dynamic sector.

Get a free price within the 24 hours!