The NPK fertilizer production line

The production line of 100.000 annual NPK fertilizer tons in Brazil

Brazil is a country with abundant natural resources and vast agricultural lands, and agriculture plays a crucial role in its economy. In recent years, with the growth of the world population and the increase in demand for food, Brazil's agricultural production has also expanded significantly. In this context, The demand for fertilizers has grown considerably. Nitrogen fertilizers, match and potassium (NPK), being one of the most used in agricultural production, provide essential nutrients for plant growth, helping to improve crop yield and quality. To meet the growing demand for high quality agricultural products in national and international markets, The Brazilian government and companies have increased investment and construction in fertilizer production. The construction of a NPK fertilizer production line with a capacity of 100,000 tons per year has attracted attention in the industry.

Custom production

world bestseller

Satisfied customers

What are the needs

company specific?

The solution

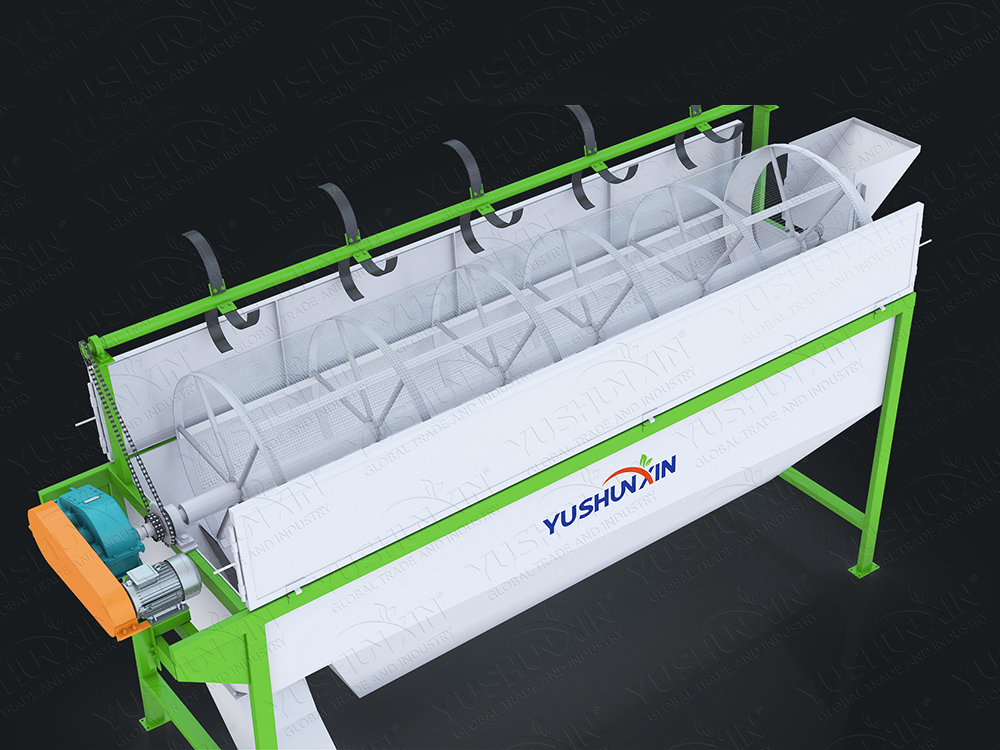

What is our solution for NPK production line?

As a professional organic fertilizer equipment manufacturer, we start from production, we give to the client to calculate the daily production per hour, according to daily production, we give the customer the appropriate recommended equipment, according to the team, we give the client to plan the layout of the plant

| Concept | Calculation | Result |

|---|---|---|

| Working days per year | 52 weeks × 5 days/week | 260 days |

| Necessary daily production | 100,000 tons / 260 days | 384.62 tons/day |

| Working hours per day | 8 hours/day | |

| Production per hour needed | 384.62 tons/day / 8 hours/day | 48.08 tons/hour |

Preparation and dosage of raw materials

The main raw materials

Main raw materials include nitrogen compounds (N), match (P) and potassium (K), as well as possible trace elements. Dynamic automatic dosing system enables high-precision dosing and continuous production, reducing human errors and increasing efficiency.

Sieving and packaging

Automated control system

Plant layout and logistics

Safety and environment

Get a free price within the 24 hours!