Manufacturing of Granulated Phosphate Fertilizer 200 TPD

Granulated phosphate fertilizer manufacturing project 200 TPD in Morocco

In the current context of global agriculture, Morocco continues to stand out as a key player in the production of fertilizers, thanks to its vast phosphate reserves. In this sense, the recent development of a granular phosphate fertilizer manufacturing plant 200 tons per day (TPD) represents a significant advance for both the country and the region. This plant aims not only to meet local agricultural needs, but also strengthen Morocco's position as a leader in the production of phosphate-based fertilizers.

Manufacturing of Granulated Phosphate Fertilizer 200 TPD

What is the investment context of the project ?

The project is designed to produce high quality granulated phosphate fertilizer, specifically aimed at improving crop yield and agricultural sustainability. With a production capacity of 200 TPD, The plant will meet both the local market and the export needs, helping to meet the growing world demand for fertilizers. This installation is a strategic investment that seeks to make the most of the country's phosphate resources and contribute to the economic development of the region.

High quality

Development trend

Customers served

sustainability

Development trend

Satisfaction Rate

The production of phosphate fertilizer granules

What is our program for the project?

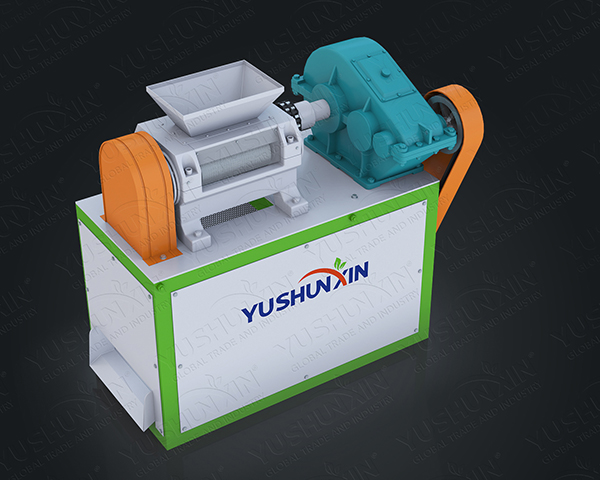

For the production of phosphate fertilizer granules, We can offer you three options: Disco granulator, Drum granulator and roller granulator. Because Moroccan fertilizer manufacturers require direct phosphate dust granulation, The roller granulator is the best option. First, The machine needs a low moisture feed material from the 5% al 10%.

Custom production

world bestseller

Satisfied customers

Company -centered practical solutions

What other equipment is included production of of granulated phosphate fertilizers?

A complete granular phosphate fertilizer production line usually includes several key equipment in addition to the granulator.. Some of these equipment are:

Crusher

Mixer

Rotary dryer

Rotary cooler

Sieve or vibrating sieve

Revolver or recycler

coating machine

Packaging system

Conveyors

Automated control system

Manufacture of granulated phosphate fertilizers

When time needed to change the mold?

The time needed to change the mold in the manufacture of granulated phosphate fertilizers is approximately six months. Besides, In real production, Customers are more concerned with corrosion resistance and the useful life of phosphated fertilizer granulator. For the manufacture of the double roller granulater Yushunxin, We use Q235 carbon steel as machine shell and 20GrMoTi as material for rollers. Therefore, it is only necessary to change the roller molds every six months, and the service life of the machine may exceed 10 years. If required, We can also provide roller granulator with 4Cr13 stainless steel roller molds, which offers high resistance to corrosion in the manufacture of granular phosphate fertilizers.

Carbon steel

stainless steel

This project not only has a positive impact on the local economy by generating employment opportunities in the region, It also contributes to the development of infrastructure and agricultural supply chain in Morocco. Besides, Plant design takes into account environmental sustainability. The technologies used are aimed at minimizing the ecological impact, reducing emissions and optimizing the use of natural resources.

Morocco has some of the world's largest phosphate reserves, which gives it a significant competitive advantage in fertilizer production. This project is part of a national strategy to maximize the use of these resources, promoting sustainable agricultural growth both locally and internationally. The plant of 200 TPD not only strengthens Morocco's position in the global fertilizer market, but also demonstrates its commitment to sustainable development and innovation in the agricultural sector.

Get a free price within the 24 hours!