How to produce gradual release fertilizer and what equipment is needed?

Production of slow release fertilizer (also known as controlled release fertilizer) It is a process that allows nutrients to be delivered to plants gradually., which can improve fertilization efficiency and minimize environmental impact. To produce this fertilizer, Which ones do the teams need?.

Steps to produce slow release fertilizer

1.Ingredient selection:

Choose the basic nutrients and compounds that will constitute the core of the fertilizer (For example, nitrogen, match, potassium, and other micronutrients).

2. Granulation

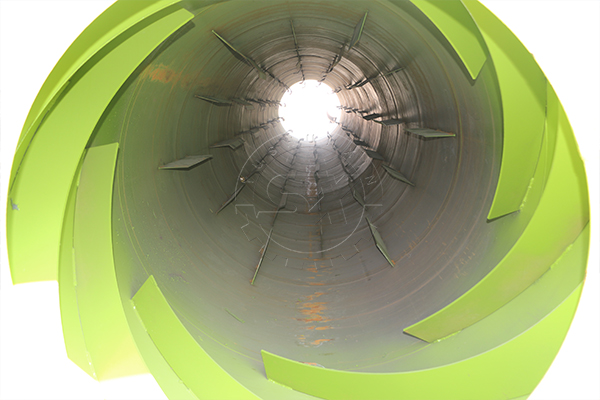

Create granules from the base material using a granulator, which can be a rotating drum, a granulating disc, or a roller compactor.

3. Covering

Apply a layer of material that controls the release of nutrients. for this, It can be used :

4. Curing and drying

After the covering, The granules are cured and dried to set the coating and prepare the fertilizer for storage and use.. A drying oven or curing room may be necessary.

5. Cooling

Coated granules may need to be cooled before being packaged or stored., for which a rotary cooler can be used

6. Packaging and storage:

Use packaging equipment to fill and seal bags or containers with fertilizer. Storage must be under conditions that prevent degradation of the product..

What equipment is needed?

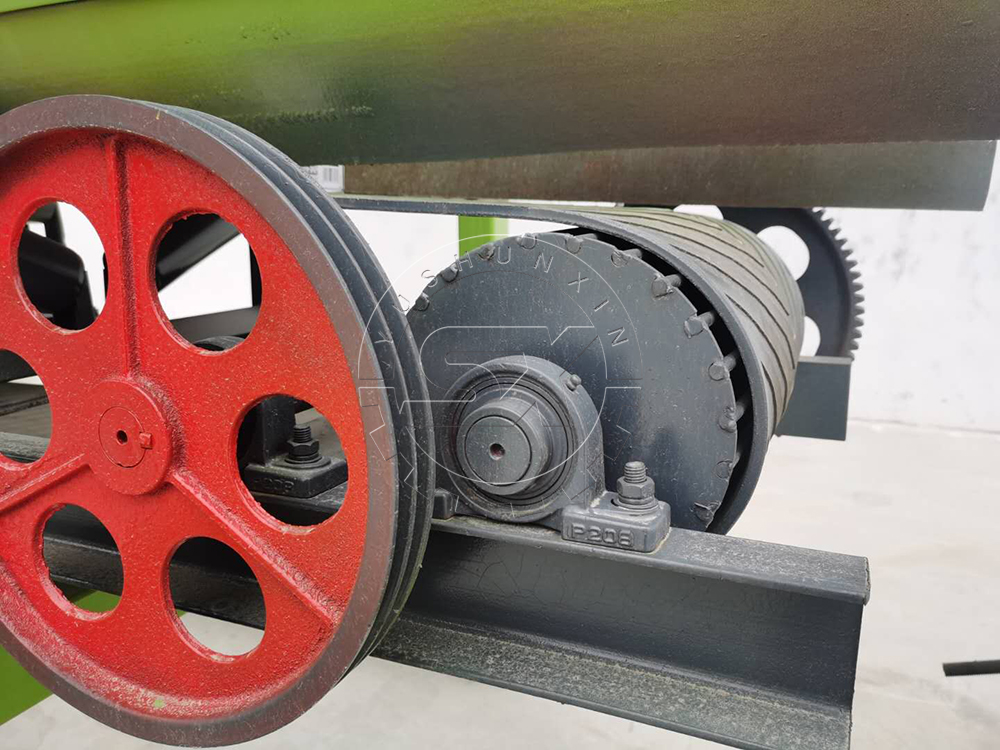

Rotary drum granulator y The rotary coating machine, which are two common equipment in the field of fertilizer production for the production of slow release fertilizers.

Features of rotary drum granulator:

Features of rotary coating machine:

Alice

Superior Plant Design Engineer

Learn more information about producing slow release fertilizer

Contact us to obtain a fertilizer production line for your plant

Rotary Dryers (Rotary Drum Dryer):

Rotary Chillers (Rotary Drum Cooler):

Selection and classification are important steps in the production of controlled release fertilizers. Its purpose is to ensure product uniformity and quality., which guarantees homogeneous distribution and effectiveness of fertilizer application in the field.

Selection process:

Classification process:

Sorting is the process of categorizing particles by size.

Through equipment such as vibrating or rotating sieves, fertilizer particles are divided into different grades.

Sorting helps meet the needs of different crops and application equipment.

En summary, Controlled release fertilizer production requires multiple carefully designed steps, as well as specific equipment. Starting with material selection, going through granulation, the application of coatings, curing and drying, refrigeration, and finally packaging and storage, Each step is crucial to the quality and effectiveness of the final fertilizer.

Throughout the production process, granulators should be used, coating machines, Dryers, soft drinks, as well as screening and classification equipment. The selection and use of this equipment must be aimed at improving production efficiency., ensure product quality and be environmentally friendly. With the cooperation of these teams, A controlled release fertilizer can be produced that not only meets agricultural needs but is also environmentally friendly..

Frequently asked questions about composting with biochar:

1.What are the benefits of using biochar-based fertilizers in sustainable agriculture??

Biochar-based fertilizers offer significant advantages, such as improving soil quality, The increase in crop production and the promotion of the nutrient cycle. Besides, help reduce dependence on chemical fertilizers, which contributes to more sustainable agriculture.

2. What raw materials are used in the production of charcoal fertilizer?

Various materials are used, like biochar, urea, CALCIO SUPEROSFATE, potassium chloride, magnesium sulphate, soil conditioners (Like potassium humato) and clay minerals. These ingredients provide essential nutrients for plant growth and improve soil properties.

3. What equipment is used in the biochar fertilizer granulation process and what are their differences??

Common equipment includes disc granulator and drum granulator. Disc granulator is suitable for small to medium scale productions, while the drum granulator is more appropriate for larger production scales. Both have their advantages in terms of cost and production capacity..

4. Why is the coating and rounding of carbon-based fertilizer granules important??

These processes improve the stability, the release of nutrients and the visual appearance of the granules. The coating protects the granules and controls the release of nutrients, while the rounding improves its appearance and resistance.

Get a free price within the 24 hours!