Double roller composition granulator

Are you looking for equipment that can process fertilizers composed of particles without drying? In the rapid development of the fertilizer industry, Production line technology without drying has received praise and support from many customers! Double roller composition granulator is key equipment. The double roller granulation machine is made of high quality materials resistant to corrosion and wear. It has many advantages, As beautiful appearance, easy operation, Low energy consumption, long shelf life and high granulos formation rate. It is an advanced equipment for the production of compound fertilizers.

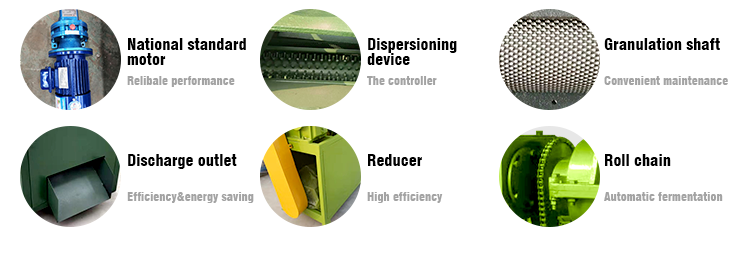

The double roller granulation machine has a wide range of applications and presents the following features:

What are the fundamental principles of your work?

First, The powder that is going to be granular is added by a conveyor belt to the feed section of the granulation machine by double rollers.

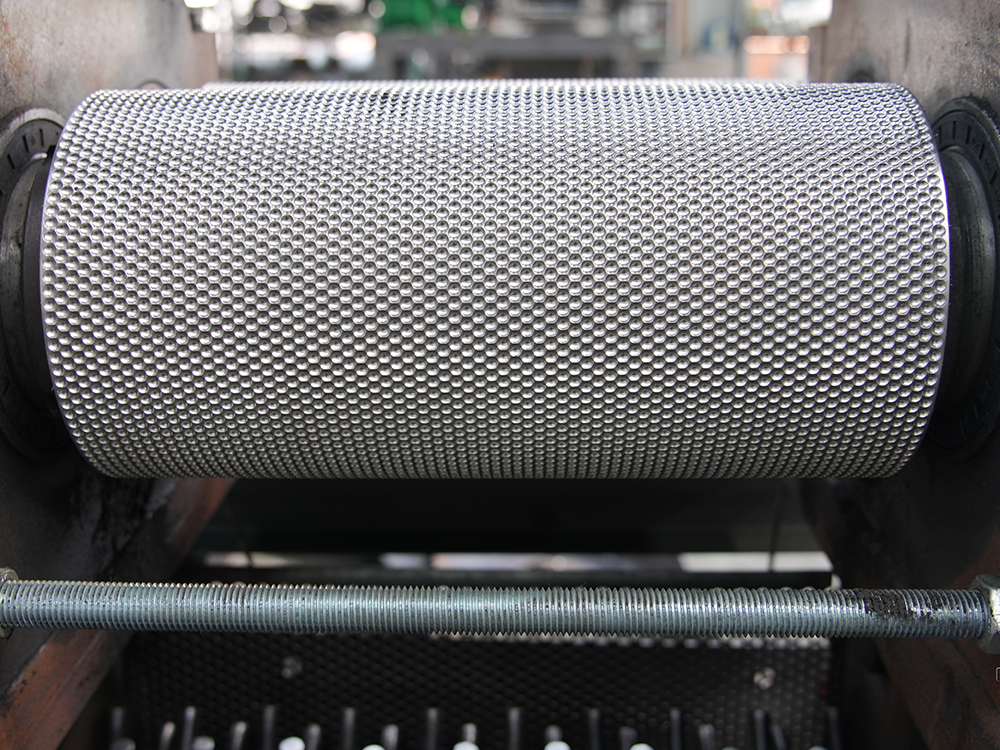

The materials are continuously attached by two parallel rotating rollers (that is to say, double rollers) and due to the external compression of the double rollers, The materials are subjected to a very high pressure. Materials gradually adopt specific form and density and form granules structure.

What is the technological process of the granulation line for roller composition?

A complete double roller granulation line is composed of crusher, feeder, mixer, double roller granulation machine, til, Packaging and Packaging scale.

First, The materials are crushed until reaching a granulometry between 50 y 100 malla, Then they feed by the feeder and are transported by the conveyor belt to the mixer. After mixing, Use double granulation rollers. The produced granules have a certain form of dust and must be sifted by sieve machine. The sifted finished granules go through the coating machine to make the granules more attractive. Those who require coating are also completed in the coating machine. Then, They can be packed and sold.

Throughout the production process of the granulation line by double rollers, No manual operation is required, which makes possible highly automated production, which saves significantly in labor costs. This in turn reduces costs and increases profits, What makes it more competitive in the market.

What differences our team in behalf of other manufacturer?

We understand that each client has requirements and needs. Includes the size and shape of pellets. As well as the capacity of the machine. So that they adjust their need.

We are proud to offer high quality equipment that is designed to last. We use durable materials and quality components, which guarantees long shelf life of our products. Besides, Our equipment is manufactured following rigorous quality standards and are subjected to exhaustive tests before being delivered to customers.

Our team is designed to offer optimal performance and high efficiency in its operation. We ensure that our teams meet the highest standards in terms of production performance, Energy consumption and final product quality.

We are committed to providing excellent customer service and technical support. Our team of trained professionals is available to help our customers at all stages, From equipment selection to installation, Implementation and after -sales service. We are committed to providing fast assistance and solving any consultation or problem they may face.

When choosing our team, You can have the confidence that you will receive custom product, High quality, efficient and backed by excellent customer service. We are committed to satisfying their needs and exceeding their expectations.

How much money a full production line of double rollers?

For each client interested in producing organic fertilizer, The price of the team is your main concern. According to the amount of production, different equipment is required. The price of the equipment increases with the amount of production. We can provide detailed and personalized information about the available equipment, its corresponding characteristics and prices. If you want to know specific prices, Do not hesitate to contact us and we will answer as soon as possible. We are delighted to help you choose the best team at the best possible price.

Technical parameters of the double roller composition granulator

| Model | Power (kw) | GRANELE Diameter (mm) | Roller leaf size (mm) | Dimensions (mm) |

|---|---|---|---|---|

| SXDG-1 T | 15 | 3-10 | 150×220 | 1450×800×1450 |

| SXDG-1.5 T | 18.5 | 3-10 | 150×300 | 1450×800×1500 |

| SXDG-2 T | 22 | 3-10 | 185×220 | 1630×850×1650 |

Get a free price within the 24 hours!