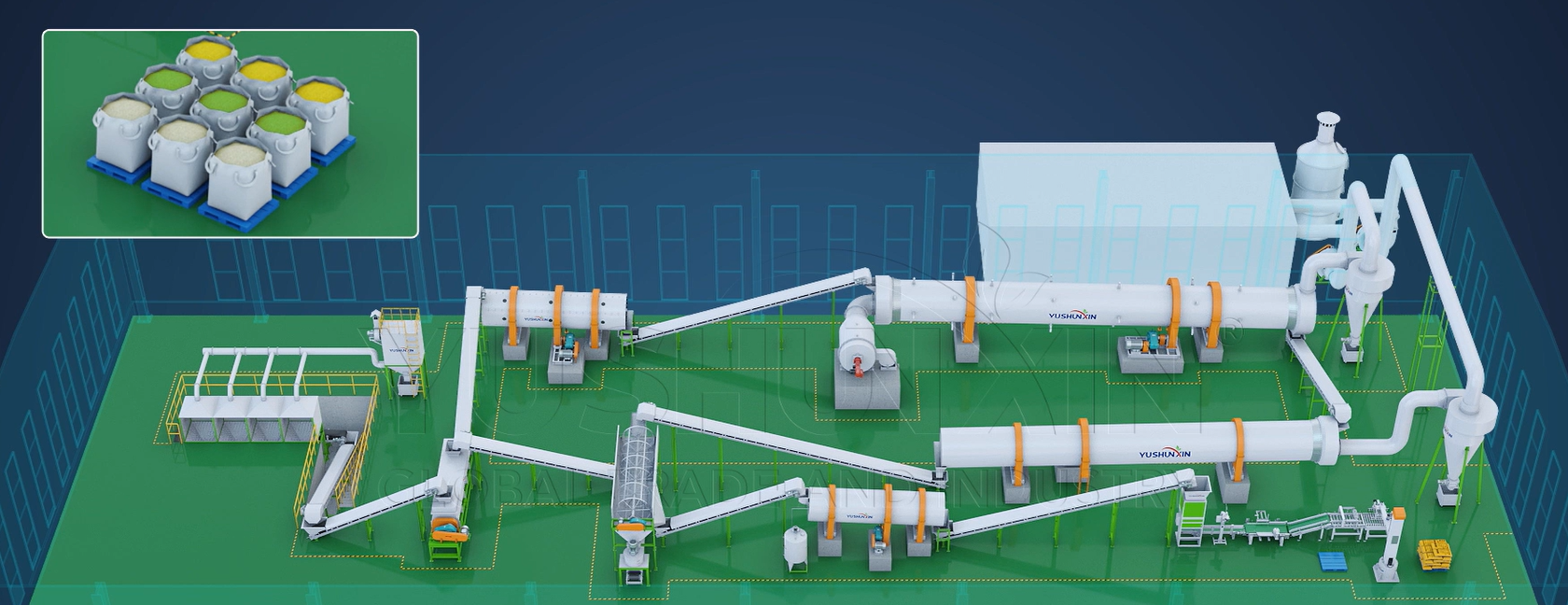

Biocarbon fertilizer production line

Biocarbon fertilizer production line

With the development of sustainable agriculture, Biochar fertilizers have received wide attention for their notable advantages in improving soil quality, The increase in crop production and the promotion of the nutrient cycle. More and more customers want to obtain benefits in the biochar fertilizer market.

As Equipment manufacturers for organic fertilizers, maintaining support for sustainable agriculture and commitment to customer success, We sincerely hope that our customers can really get profits with our teams and master the biochar fertilizer market.

Preparation of raw materials for vegetable -based fertilizers

Soil conditioners, Like potassium humato, They can have a positive impact on the ground on several levels:

Long -term use of chemical fertilizers can lead to a decrease in soil pH, resulting in problems of excessive acidification. Wet acid is a natural organic substance with some damping capacity, that can help regulate soil pH and reduce the risk of excessive acidification. Potassium ions in potassium humato can also act as necessary nutrients for plant growth.

Wet acid helps to form a good soil aggregate structure, which is crucial for soil aeration, Root drainage and growth. A soil with aggregate structure can better retain moisture and nutrients, And it is also more suitable for the activity of microorganisms, All favorable conditions for plant growth.

During the manufacturing and granulation process of fertilizers, Different ingredients can have different acid-base properties. Potassium humm can act as a regulator, helping to balance acidity or alkalinity in the mixture, which is beneficial for the stability and effectiveness of fertilizer. When balancing the pH, The effectiveness of the different nutrients in fertilizer and their interaction ensures, thus improving the general effect of fertilizer.

Therefore, The addition of Potassium Humato or other soil conditioners to biochar fertilizers can not only improve the nutritional value and fertilizer effectiveness, but it can also help improve soil health after prolonged use of chemical fertilizers, which favors the implementation of sustainable agriculture and the protection of soil resources.

Through efficient dosing and segregated storage control of the automatic dosing machine, human error can be significantly reduced, Increase production efficiency and at the same time ensure the balance of nutritional elements in coal -based fertilizer products.

About the team

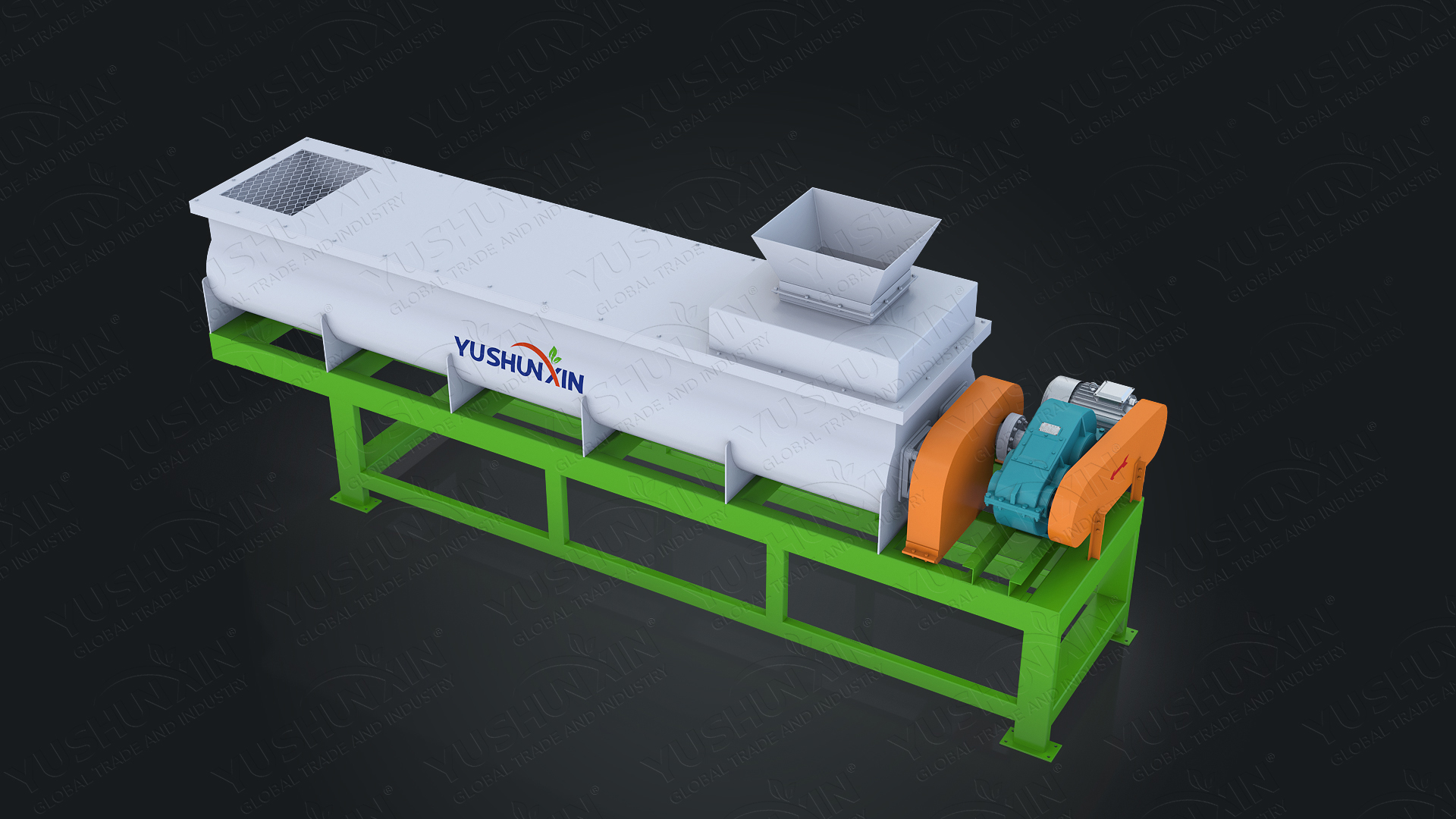

Mix raw materials

To ensure that the various raw materials are completely mixed, It is necessary to use mixer to fully shake them. Our Horizontal double axis mixer It has advantages such as a uniform mixture and a robust power, which allows the different ingredients of coal -based fertilizer to mix evenly.

Quality equipment

Mixing capacity

Product Quality Index

Energy Generation

In the biochar -based fertilizer production process, Wet granulation is a common method that implies converting material into granules under specific liquid conditions to facilitate application and improve fertilizer efficacy. According to the production scale, You can choose different types of granulation equipment:

Disco granulator

Also known as Plate granulator, Suitable for small -to -scale production. The disk granulator uses a rotating surface for, through the centrifugal force of the material and the action of an binding, granular the material. This machine has a simple structure, a relatively low maintenance cost and is easy to operate, But its production is rather low.

Drum granulator

Also known as Rotary Drum Granulator, Suitable for large -scale production. The drum granulator has a large rotating drum where the material is mixed, granula and form. This type of equipment has greater production and can handle larger lots of material, But the cost of the equipment and the operating costs are usually higher.

For large -scale production of biochar fertilizer, It is recommended to use a drum granulator or a combination of disc granulator and drum granulator for a second granulation, which can improve the quality and uniformity of Biochar granules. The second granulation implies processing the preliminary granules once again in the granulator to increase the strength and shape of the granules and improve the general quality of the product.

Regardless of the team that is chosen, The key is to perform the proper pretreatment of the material, Adjust the moisture and amount of binder aggregate to ensure that the final biochar fertilizer granules have good physical properties and nutritional uniformity.

Coating and rounding

If special requirements are needed for fertilizer granules, how to improve stability, slow down the release of nutrients or improve visual quality, Coating and rounding processes can be used.

The coating machine It is a equipment designed to apply one or several layers of protective coating on the surface of fertilizer granules. This protective layer can be made of polymers, Calcium sulfate, Organic matter, etc., And not only protects the granules of erosion and damage, but it also allows controlling the speed of release of nutrients as necessary.

The rounding machine, on the other hand, It is used to improve the appearance of the granules. Through the mechanical polishing action, makes the surface of the granules softer, Round and attractive. This not only improves the visual quality of the granules, but also helps reduce break and wear during transport and application.

After the coating or rounding process, The following steps are Drying and cooling.

Drying machine

Drying is a critical stage where the remaining humidity of fertilizer granules is eliminated to guarantee their stability and avoid degradation or agglomeration. One is used Drying machine, as a rotary dryer, where the granules are heated and allowed to pass through a hot air flow, which eliminates excess water.

Cooling machines

Once the granules are dry, They are transferred to the cooling stage to reduce their temperature before packaging. Cooling is important to avoid moisture condensation on the surface of the granules when they come into contact with the coldest air outside the dryer, which could cause fertilizer caking or agglomeration. Cooling machines, Like rotary coolers, They use cold air to lower the temperature of the granules efficiently.

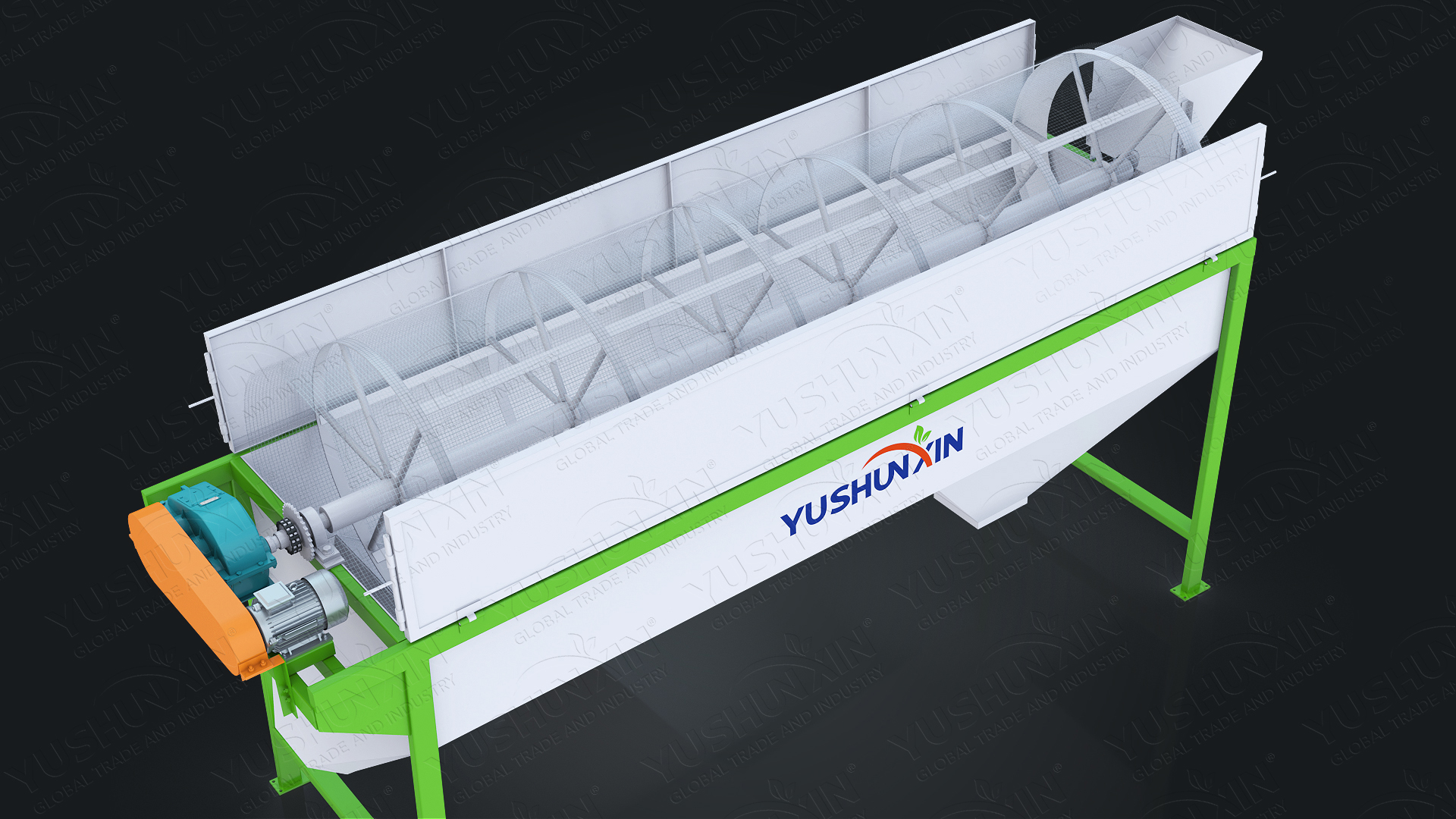

Sifted to classify coal -based fertilizer particles

After completing the drying process, A sieve machine can be used to classify the coal -based fertilizer particles by size. Sieve is an important step that helps ensure the consistency and quality of coal -based fertilizer, complying with product specifications. In general, The sieve machine allows particles to pass with a size range between 1 a 5 mm.

During the sieve process, Dry coal -based fertilizer particles are introduced into The sieve machine, which commonly contains several meshes with holes of different sizes. These meshes can effectively separate particles that are too large or small, allowing only the passage of those particles that meet the specified size, while the particles that do not meet are separated to be recycled or processed later.

Coal-based fertilizer particles that are too large need to be crushed again or returned to the previous production process to be re-processed. The particles that pass the sieve and are of adequate size can go to the next production stage, Packaging and storage, preparing for sale or use.

LBiochar -based fertilizer production is a systematic engineering project that requires the coordination of several equipment and technologies. From the preparation of the biochar to the packaging of the final fertilizer, Each step is crucial. Optimizing production flow and team selection, Not only can the quality of biochar fertilizer be improved, but also increase production efficiency, reduce costs and, as equipment suppliers, We are committed to providing good service to our customers. We welcome customers who are considering investing in the production of organic fertilizers to collaborate with us.

Get a free price within the 24 hours!