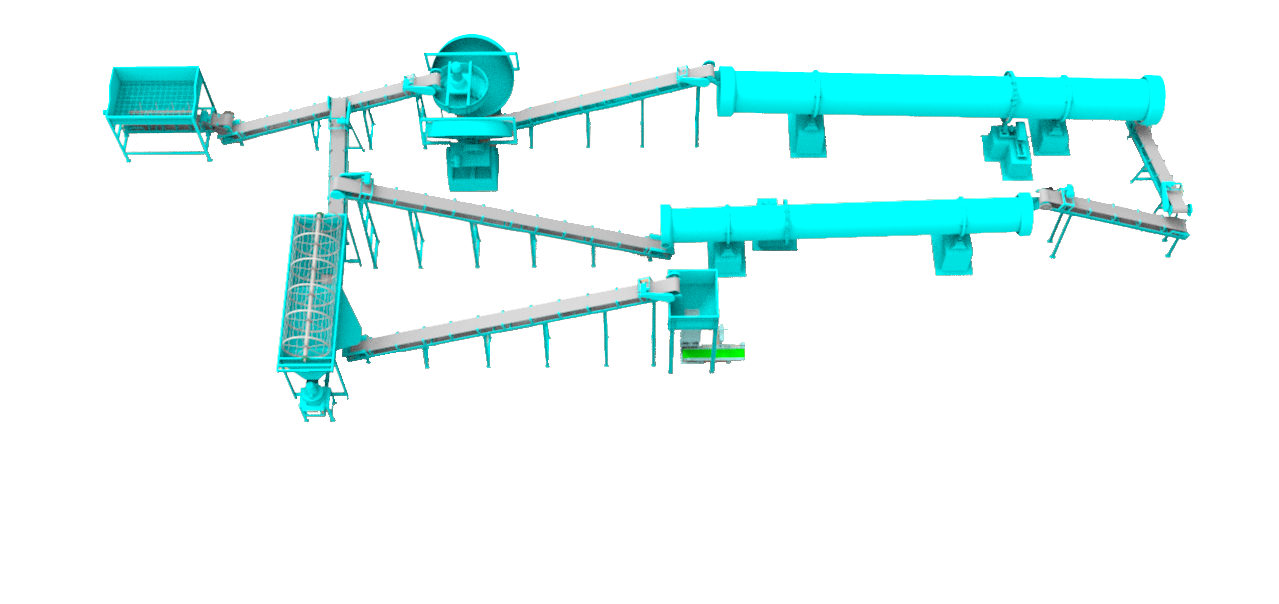

Microbial fertilizer granulation project

Microbial fertilizer granulation project

Project of Microbial fertilizer granulation

With the advance of sustainable agricultural development, Microbial fertilizers are gaining popularity in the market due to their environmental advantages and their ability to improve soil fertility. This project aims to produce highly efficient microbial fertilizers using diatoms land, Zeolite, Microorganisms and humic potassium acid as raw materials, by one Disco granulator.

SELECTION OF RAW MATERIALS

What are microbial fertilizer granulation process?

crusher

Raw materials as diatoms land, Zeolite and humic potassium acid are mixed in specific proportions and are finely pulverized to ensure the uniformity and effectiveness of granulation.

High quality microorganism strains are selected and largely grown in adequate culture media to obtain high microbial cultivation concentrations.

Pretrated raw materials are mixed with microbial culture in specific proportions to ensure a uniform distribution of microorganisms in raw materials.

Drying and cooling

Newly granulated particles have a high moisture content and require a Drying appropriate, generally by low temperature drying to protect microbial activity. Then, particles cool to stabilize their shape.

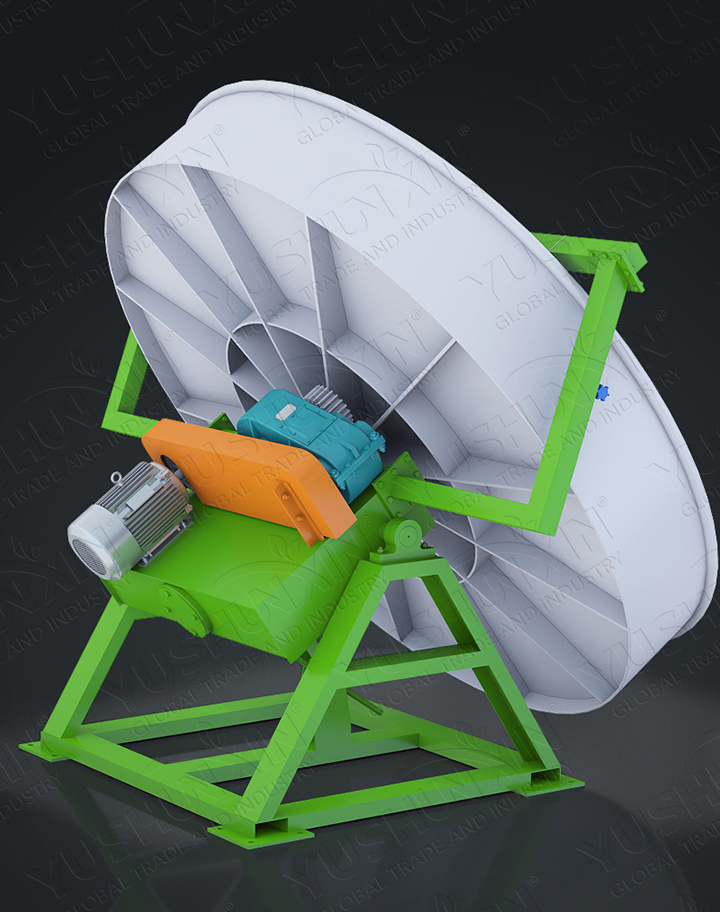

Granulation

The resulting mixture is introduced into the Disco granulator, adjusting the speed and size of the particles. Through the rotation and friction of the disk, The particles are formed uniformly.

Sifted and packaged

Dry and cooled particles are sifted to eliminate non -compliant products and, finally, They are packaged and stored.

Team selection for granulation of microbial fertilizers

Disco granulator:Disco granulator They present numerous advantages in fertilizer production, especially in the context of the manufacture of microbial fertilizers and other types of organic fertilizers.

What are the advantages of our album granulator?

3. Energy efficiency

Disco granulator They are designed to be energetically efficient, which reduces production operating costs. Its energy consumption is relatively low compared to other types of granulation equipment.

Microbial fertilizer granulation project

Energy Generation

Quality Index

Product Quality Index

Energy Generation

This project uses a scientific selection of raw materials and a reasonable optimization of the production process to produce efficient microbial fertilizers through a disk granulater. After the implementation of the project, Not only has production efficiency and product quality be significantly improved, but notable economic and social benefits for the company have also been achieved.

Get a free price within the 24 hours!