Flat matrix granulation production

feed for animals

feed for animals

Feed production with Flat matrix granulation

Some time ago, Our company received a consultation from Peru. The sender is a farm farmer in Peru, who showed great interest in our flat matrix granulator. This farmer wishes to use the granulator to produce animal food, In order to meet the needs of your farm. According to your description, Raw materials for food include crushed corn, wheat, crushed barley, soy cake, as well as mineral salts and vitamins.

What are the needs of the client and its production objectives?

Through detailed communication with the client, We understood your specific needs and production objectives:

After understanding these needs, We begin to prepare a detailed plan of the project and propose appropriate solutions for the client.

What is the project plan we give to our clients?

Pretreatment of raw materials

- 1

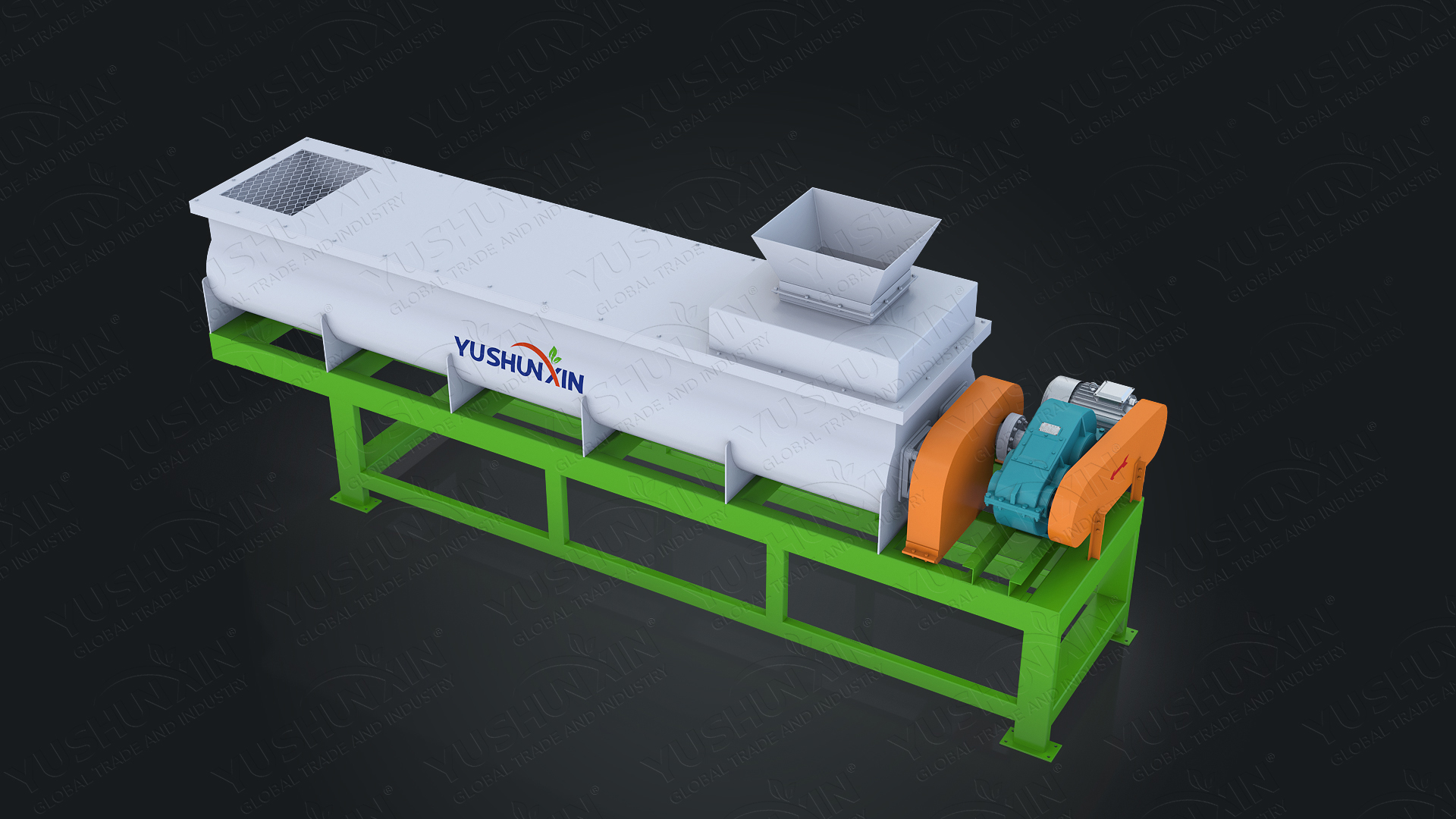

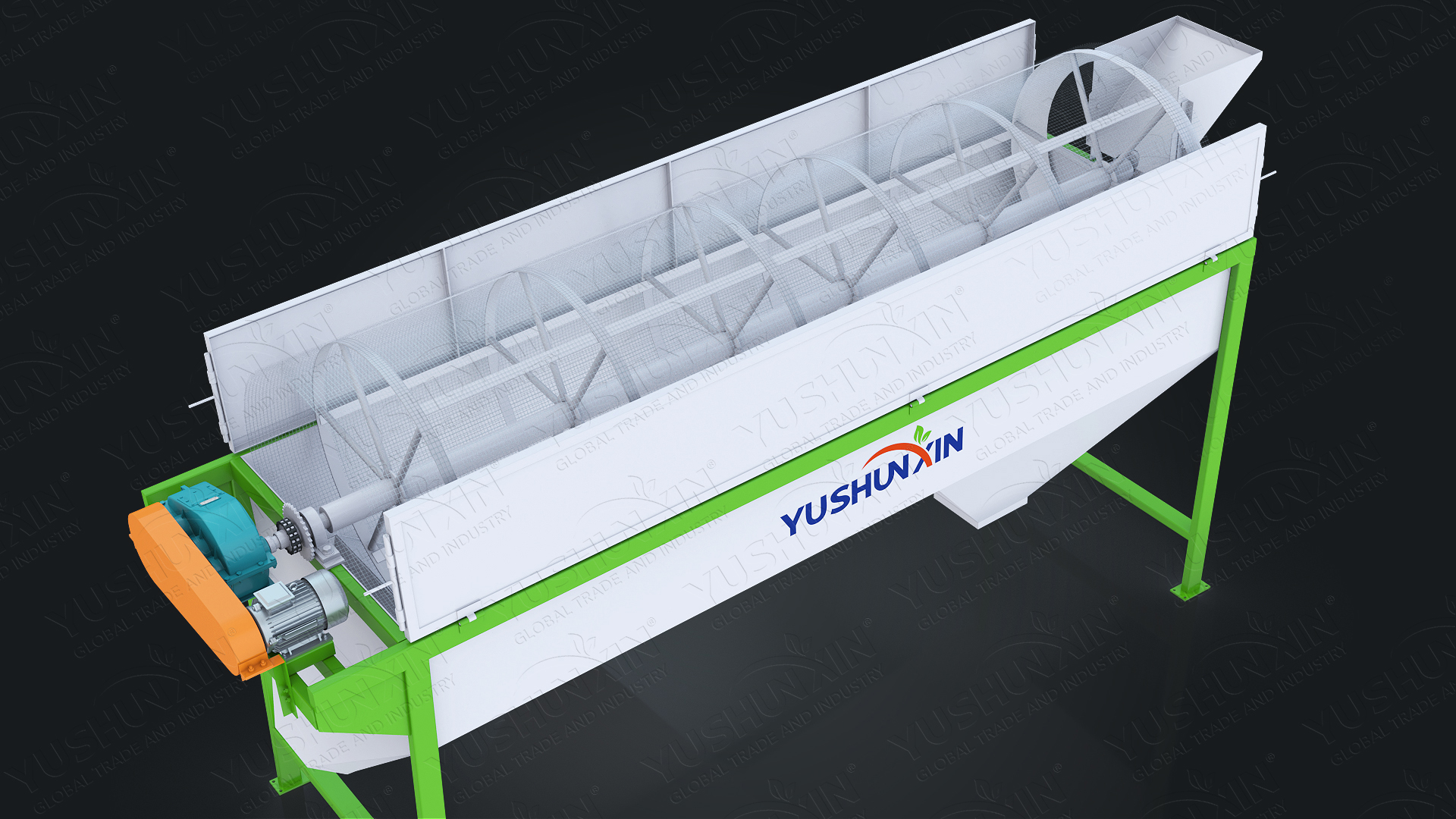

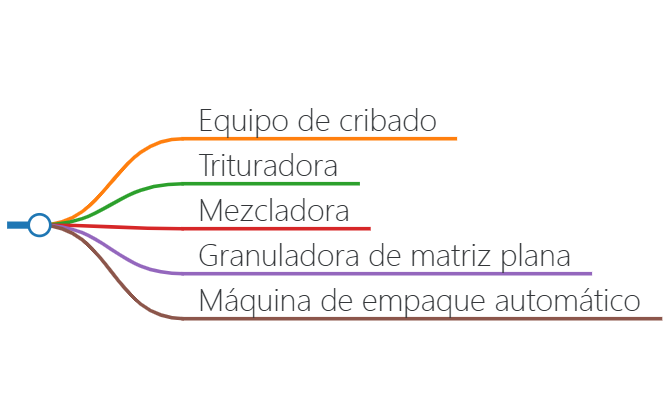

Impurities elimination: Use a screening equipment to make a crushed corn pre -selection, wheat, barley crushed and soy cake, eliminating stones, metals or other impurities.

- 2

Crushing and mixing:Make a second crushing of the soy cake to ensure that raw material particles meet the production requirements. Mingle uniformly crushed corn, wheat, crushed barley and soy cake according to the proportion.

Flat matrix granulator

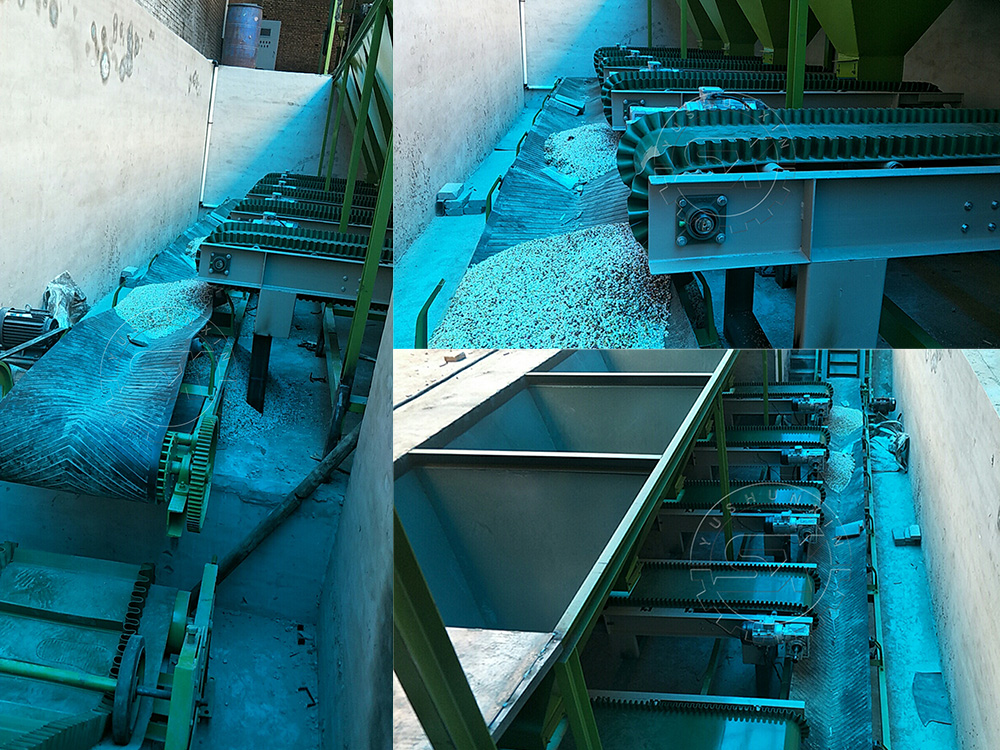

Introduce the raw materials mixed evenly in Flat matrix granulator.

The flat matrix granulater heats and compresses raw materials through the mold holes to form food pellets. Control temperature and humidity to ensure the quality of pellets.

Cooling and drying

In general, No additional drying treatment for granulated equipment is required by flat matrix granulators, But if the moisture content of the granules is high, Additional drying can be carried out by means of a dryer to avoid the deformation and mold of the granules.

Packaging and storage

How does product quality control during The entire production process?

Share your wedding moments with your guests

1.Raw material inspection

Ensure that all raw materials go through a strict quality inspection before entering the production line.

What is the reaction of customers and what follow -up services we offer?

After installation and setting of the equipment, We make several monitoring visits and provide detailed training in customer operation. The client expressed great satisfaction, considering that the team works stable, It is easy to operate and has improved the quality of the food produced. He mentioned that this line of equipment has not only increased production efficiency, It has also reduced operating costs, further improving the competitiveness of his farm in the market.

Later, We continue to provide technical support and after -sales service to the client, ensuring the long -term stable operation of the equipment. We also help the client optimize the food formula, making it more appropriate for the nutritional needs of different animals.

Through this case, Not only do we help the client solve practical problems, but we also demonstrate the professional capacity of our company in the manufacture of equipment and project management. We hope to collaborate with more customers in the future to jointly promote the development of animal food production technology.

Get a free price within the 24 hours!