The organic fertilizer line of pork manure

The organic fertilizer line of pork manure

The organic fertilizer line Pork manure

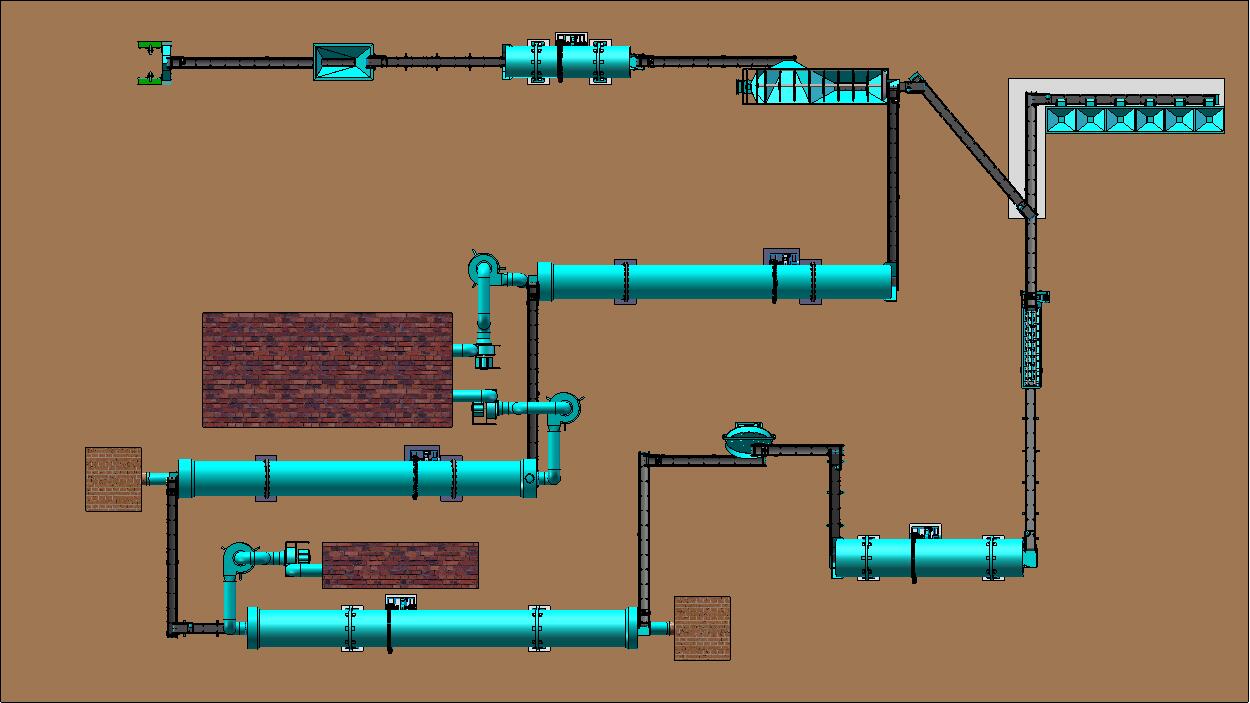

The basic principle of organic fertilizer is mixing organic materials such as manure and urine with crushed straw, submit them to natural or aerobic fermentation by adding Microorganisms To convert organic matter into stable humus.

How to make composting and how to choose the equipment?

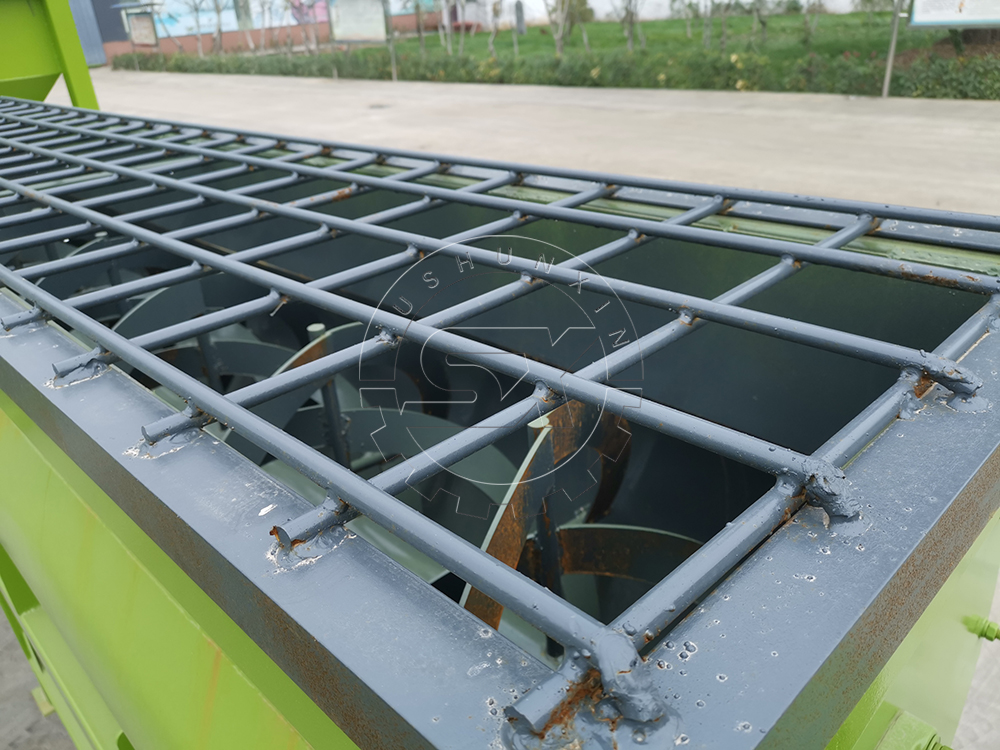

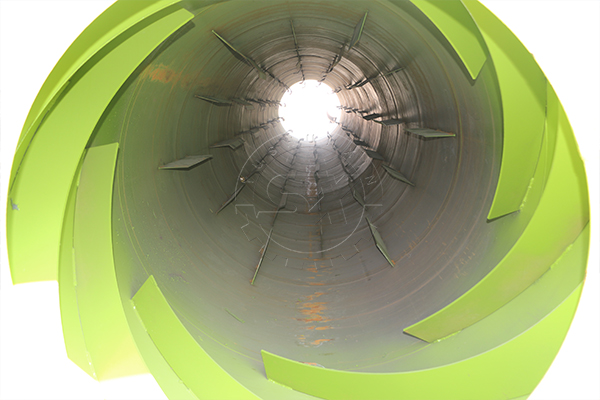

Completed the dehydration of the feces, The next step is fermentation. Periodic removal promotes the process of fermentation of organic materials. When turning the materials, ventilation is improved and oxygen supply is increased, which stimulates the growth and activity of beneficial microorganisms. For a can, The turn mixes the external and internal layers of the pile, distributing temperature more uniformly, humidity and nutrients, which favors a balanced fermentation in general. On the other, Voltage avoids overheating or insufficient fermentation of the pile, thus improving the quality and stability of organic fertilizer.

Get a free price within the 24 hours!