What are compound fertilizers?

Compound fertilizers are those that contain two or more nutrient elements, like nitrogen, match y potassium. They have the advantage of having high nutrient content, a low amount of secondary components and good physical properties. They play a very important role in promoting high yields and stability in crops..

How to make compound fertilizers?

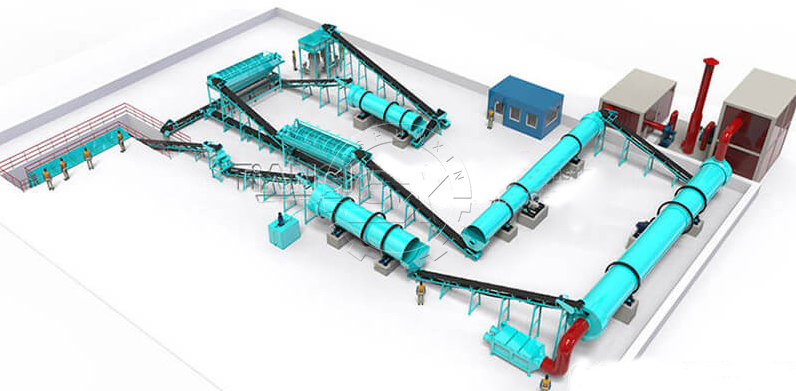

Compared to organic fertilizer, the production of compound fertilizers requires stricter requirements. Not only specialized knowledge and skills, as well as adequate proportion and control of ingredients. From raw materials to final pellets, all steps are important. In first, Ingredient selection: Choose the right ingredients that contain the nutrients you want to combine in the compound fertilizer. In general, ingredients such as phosphate are used, nitrate, potassium sulfate or chloride, urea, etc.

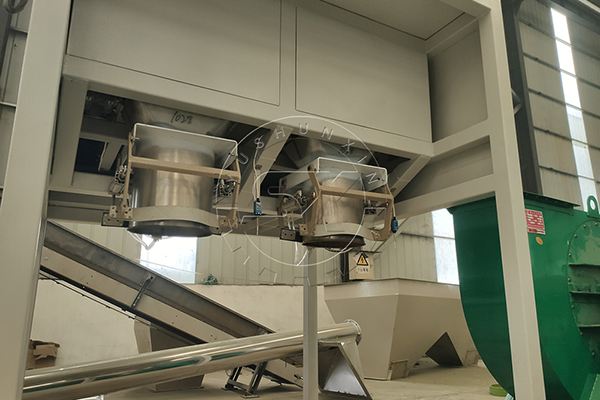

Dynamic automatic batching system for compound fertilizers

For the production of compound fertilizers, It is essential to precisely mix the ingredients in exact proportions. This ensures that essential nutrients. Be present in the right amount to meet the needs of the plants. Besides, Precise mixing prevents overdose or lack of nutrients. Can have negative impact on plants and the environment.

Our dynamic automatic dosing system can ensure the precise mixing of nutrient ingredients according to the set proportion.. It has a reliable feedback control mechanism that adjusts according to actual circumstances., ensuring the stability and precision of the ingredient process.

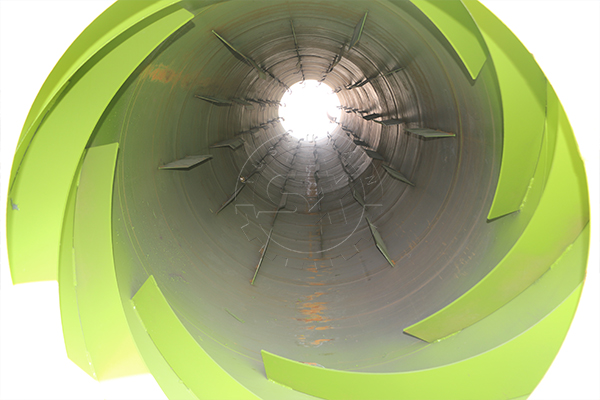

Compound Fertilizer Line Drum Mixer

Place the ingredients prepared by the dosing machine in the mixer and mix well.. To ensure uniform distribution of nutrients in the compound fertilizer. This mixing process ensures that compound fertilizer contains adequate proportion of nutrients.. The mix complete is key to achieving high quality and effective compound fertilizer. Our compound fertilizer drum mixer is more suitable selection. The machine mixes uniformly,continuous production.

Its production capacity up to 30-40 tons per hour. The machine body is made of special material. It is highly efficient and wear resistant. Besides, Internal lining with corrosion protection can be customized according to customer needs.

Compound Fertilizer Crushing Machine

Between the mixer and the granulator, you can add a Crushing machine. The crusher can crush the material and ensure the required uniformity and particle size. Besides, if non-conforming products are found during the subsequent screening process, They can be sent back to the crusher to be crushed and granulated again., so that they meet the required standards. This process can improve product quality and reduce waste.

New Type Organic Fertilizer Granulator and Rotary Drum Granulator with Teeth

For the granulation of compound fertilizers, You can choose new type organic fertilizer granulator or rotary drum granulator with teeth. The first has approximate production of 4-6 tons per hour. While the latter can reach a maximum production of 5-8 tons per hour. Compared to the last, the first has a higher rate of granule formation.

These two granulation machines mainly use wet granulation technology. By adding adequate amount of water, materials in powder form are converted into granules under the action of the rotation of the machine body.

Rotary Drum Drying Machine and Rotary Drum Drying Machine

It is necessary to eliminate excess moisture from the granules of its organic fertilizer to meet the international moisture content requirements for organic fertilizers (14%).These two machines are excellent options for processing compound fertilizers.

Compound Fertilizer Rotary Screening Machine

To obtain compound fertilizer granules uniform in size, It can be used The screening machine to separate the granules. Granules that do not meet the requirements or are too large can be subjected to a crushing process and subsequently the formation of new granules..

Compound Fertilizer Rotary Coating Machine

To prevent clumping of compound fertilizer due to long-term storage. It is recommended to coat the previously dried granules. rotary coating machine, using powder dusting and liquid application methods, can be used to apply coating effectively. This process helps prevent clumping of the compound fertilizer and maintain its quality over storage time..

Automatic packaging scale

The packaging It is the final phase of the organic fertilizer production process. After being packed, Organic fertilizer can be transported and stored more conveniently, And you can also sell more specific to different customers.

- Our feeder has many advantages, as great traction capacity, Low energy consumption, smooth operation and long life. It is very suitable ideal option for you.

Get a free price within the 24 hours!