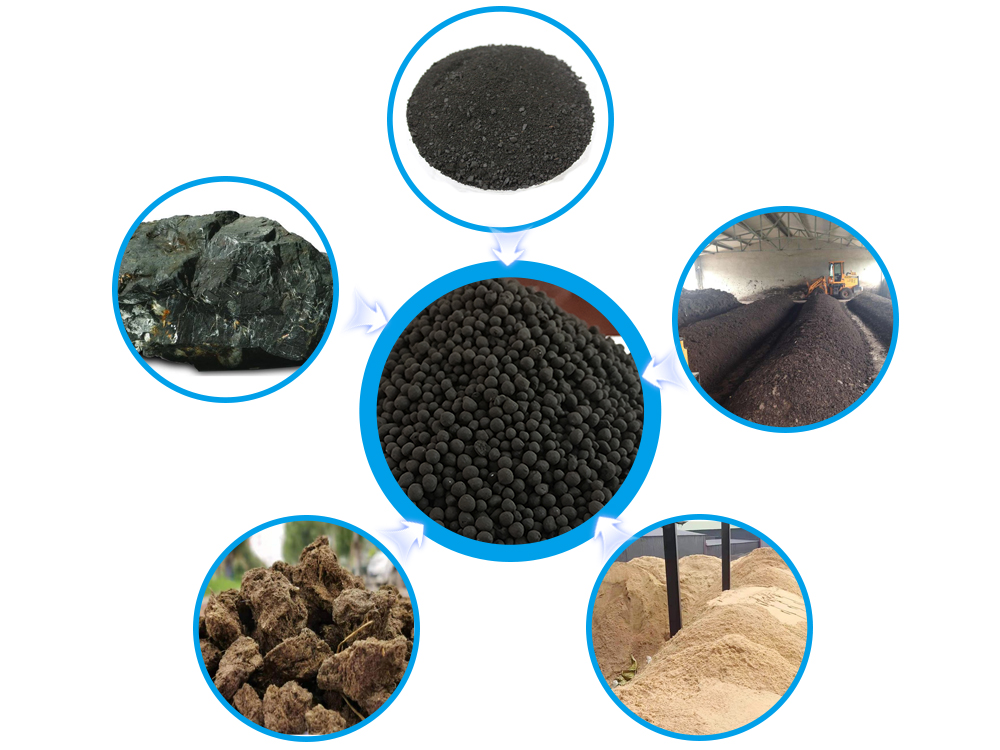

ELABORATION Granulated organic fertilizers: using animal manure, phosphoric rock, leonard, industrial waste

According to the United Nations Food and Agriculture Organization, To meet the needs of the world population, chemical fertilizers have been used indiscriminately, causing repercussions on the environment and human health. Granulated organic fertilizers is a sustainable practice that contributes to soil fertility and crop improvement, Taking advantage of organic and industrial waste. Hoy, We explore a way to do it: ELABORATION Granulated organic fertilizers: using animal manure, phosphoric rock, leonard, industrial waste.

Materials selection

Composting and how to make compost?

Collect animal manure as cows, pig, Horses, sheep, The Birds, which will serve as basis for fertilizer due to its high nutrient content. Contact farms and farms in the area to explore the possibility of collecting your manure. Farm owners often look for ways to get rid of the manure that accumulates, So this can be a beneficial collaboration for both parties.

Next, one has to Dehydrate the manure collected animal. Dehydration of animal manure is an important step in the process of transforming it into a more manageable and useful product as a fertilizer. The reduction of moisture content not only facilitates the management and transport of manure, It is also crucial to reduce the risk of pathogens and minimize odors.

Alice

Superior Plant Design Engineer

Learn more about solid-liquid separation equipment

For this step, our solid-liquid separation equipment They present the following advantages:

Dehydrated animal droppings cannot be used directly to make pellets, It is necessary to perform a composting process.

Composting process

This is an aerobic process that transforms organic matter into compost through microbial activity in the presence of oxygen. During composting, The material turns regularly to ensure aeration, which accelerates the decomposition process and stabilizes organic matter. The resulting compost is a fertilizer rich in nutrients.

During the composting process, It is possible to add organic industrial waste, as long as these are biodegradable and do not contain pollutants that may affect the quality of compost, human health or the environment. The inclusion of these materials can be beneficial because it provides a variety of nutrients and structure to compost.

Therefore, By adding industrial waste to composting, It is essential to consider the C ratio:N, since it is a critical factor for efficient composting. A balanced proportion is generally found in the range of 25-30 Carbon parts for each part of nitrogen. Excess carbon can slow down the decomposition process, while an excess of nitrogen can cause odors and the loss of nitrogen in the form of ammonia.

About this process, We can recommend that you use a Wheel Volteadora or one Power turner. Both are the most commonly used equipment for large -scale rum of organic fertilizers.

Alice

Superior Plant Design Engineer

Learn more information from Vista Maplers

On phosphoric rock crushing:

Phosphoric rock is a non -metallic mineral that contains high phosphate concentrations, which are chemical compounds of phosphorus. This mineral is an important raw material used in the production of phosphate fertilizers, which are essential for plant growth due to their role in energy transfer, photosynthesis and nutrient transformation.

Crushing method: There are many types of equipment and technologies for rock crushing, Here we recommend that you use the vertical mill, which is a common -use grinding equipment for medium hardness minerals. With a unique structural design, You can achieve fine grinding and granulometric classification of the product through the classification system.

Of course, You can also buy phosphoric rock powder directly in the market.

About Leonardita crushing

The Leonardita is a type of dark brown lignite, soft and earthy, which is a form of low quality coal. However, The Leonardita is valued by its high content of humic acid and other humic substances, which are excellent to improve soil quality, acting as soil conditioners and plant growth stimulants.

Crushing method: Like phosphoric rock, You can buy equipment or powder directly on the market.

About Composting Crushing

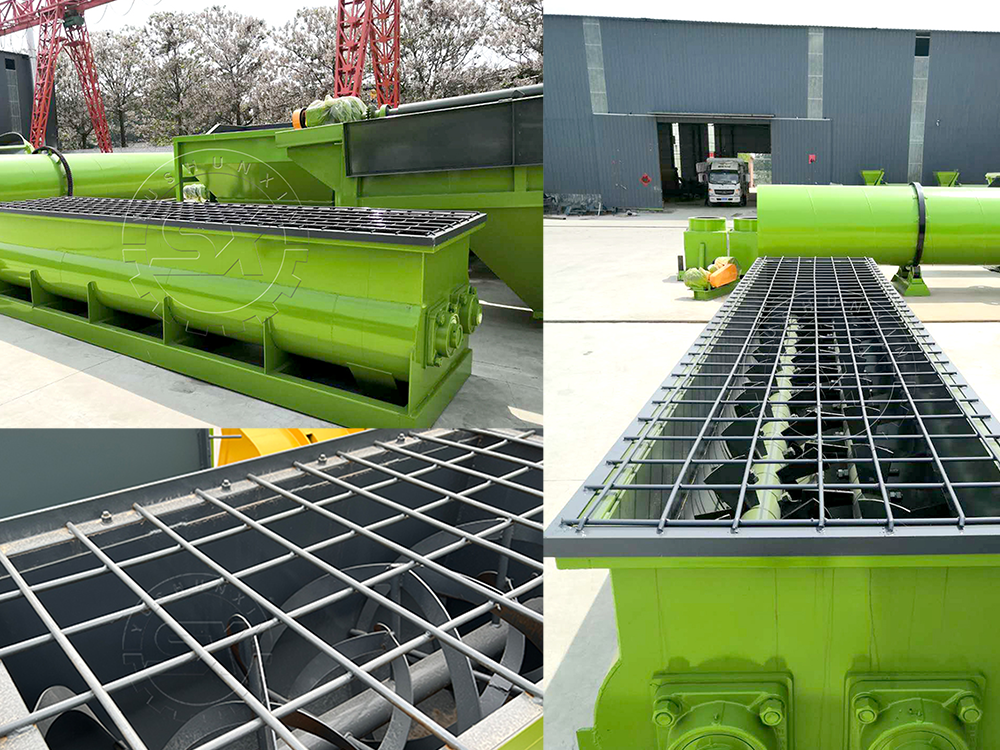

After the composting process, It is common for the resulting compost to contain particles of different sizes and lumps. These lumps can be the result of materials that were not completely decomposed during composting, o They can be formed during compost storage and manipulation. To improve uniformity and facilitate compost granulation, It is often necessary to perform a crushing or grinding additional.

Sifted:

after crushing, It is useful to pass compost through sieves or screening To separate particles from different sizes. The finest particles can be used directly, while the largest pieces can be redirected to the crusher.

Mixture and dosage

Combine all materials (Phosphoric rock, Leonardita and others) In the appropriate proportions to ensure that the fertilizer contains an appropriate nutrient balance for the needs of the crops to which it will be allocated.

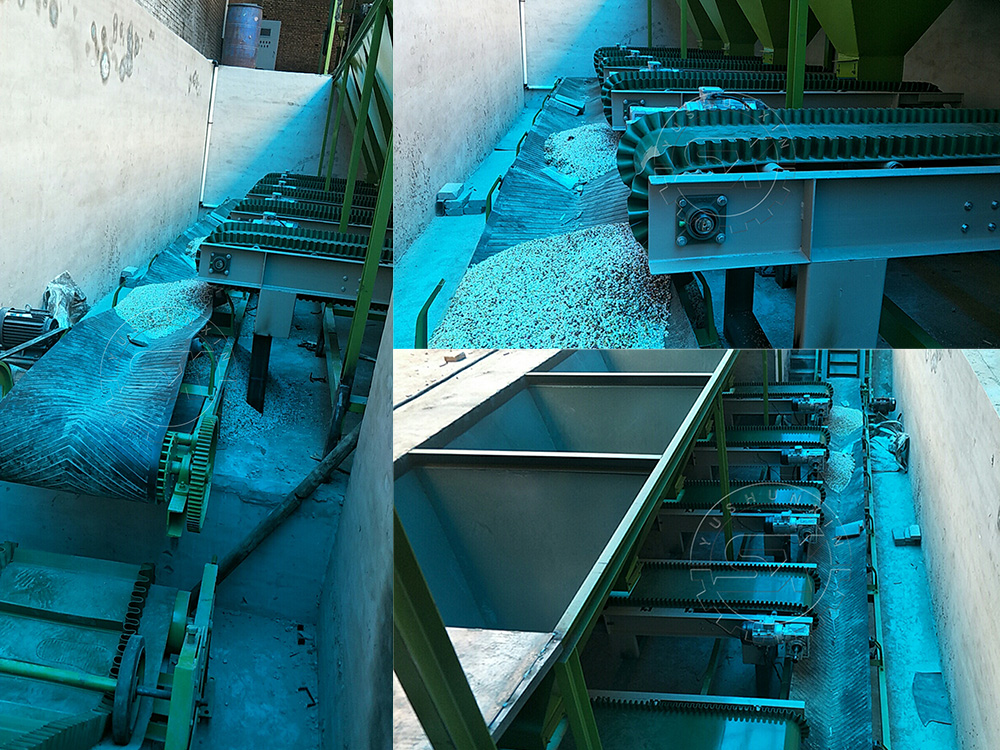

Pelletization process

The next step would be pelletization:

Drying and cooling

Alice

Superior Plant Design Engineer

Learn more project information

Packaging and storage:

PACK THE SUPPLY SAIL OR CONTAINERS FOR HANDLING AND STORAGE. Make sure the storage place is dry and protected from pests.

In this process, You can use our Automatic packaging machines.

Through the use of these waste (Animal and industrial waste set) In the elaboration of organic fertilizers, Sustainable agriculture is promoted and the environmental footprint associated with the excessive use of synthetic chemical fertilizers is reduced, contributing to soil health, Food security and environmental protection.

Get a free price within the 24 hours!