New type of organic fertilizer granulator

New type type of organic fertilizer is commonly used in the wet process of organic fertilizers granulation. Due to its high granular formation rate, Stable and long shelf operation, This team has become the ideal option for many customers.

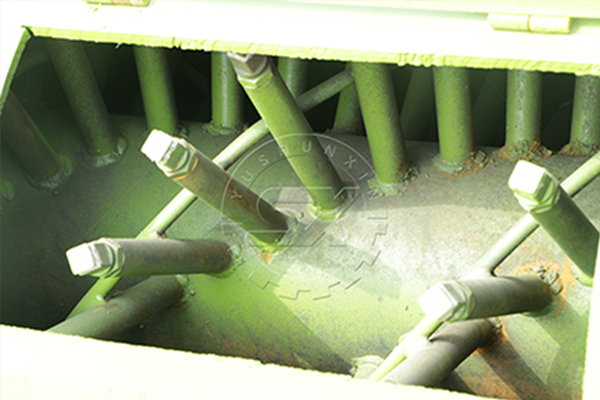

What is the main principle of operation of the machine?

Organic fertilizer granulator of new type uses the mechanical force of high speed mixing and the air dynamics generated by it to achieve continuous mixing processes, Granulos formation, spheroidización, compaction, etc. Inside the machine in order to achieve the purpose of granulation.

What is the size of the particles and the granulos formation rate of this equipment?

The shape of the particles is spherical, with a degree of sphericity ≥0.7 and a diameter that usually ranges between 0,3 y 3 mm. The granulos formation rate is ≥90%. The diameter size of the particles can be adjusted properly by the amount of material mixture and the main shaft rotation speed. In general, The lower the amount of mixing, The greater the rotation speed and smaller will be the particles, and vice versa. The organic fertilizer granules produced by this machine have a greater hardness compared to those produced by the rotating drum and disc granulation. The hardness of the granules is between 20-25n.

What are your application scope?

The new organic fertilizer granulation machine is especially suitable for the granulation of light and thin dust materials. The finer the basic particle size of the material powder, greater will be the degree of sphericity of the particles and will better be the quality of granulos formation. The typical materials used include Chicken manure, Pork manure, Vaca manure, crowd, clay, kaolin, inter alia.

What are the moisture requirements before the granulation process?

Because the granulation process is wet, a moisture treatment of the material is required before food. The recommended feed humidity for this machine is 20% al 40%. This machine It is more appropriate for direct granulation of organic fertilizer after the fermentation process, which saves costs in the drying process and significantly reduces production costs.

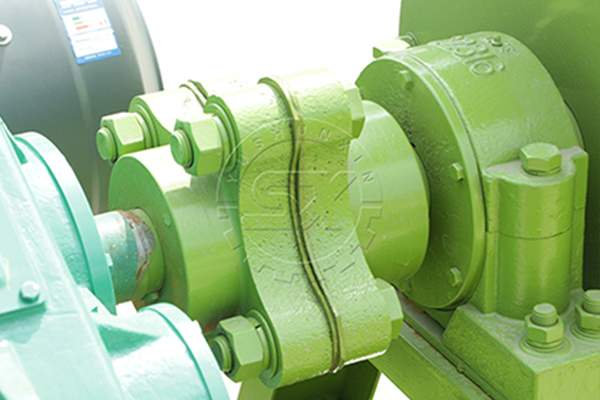

What is the main material of the machine?

The machine is made of 20cRMN material, harsh 55 HRC. This material is suitable for the manufacture of machine components that need to support large friction or impacts. At the same time, Due to its excellent resistance to corrosion, This material is suitable for organic fertilizer granulation. Since it does not oxidize easily or harm. This prolongs the life of the machine, Improves your reliability and stability, Reduce maintenance costs and parts replacement frequency.

What is the capacity of the machine?

Because the production needs of each customer are different, Granulation production requirements also vary. According to the required production capacity, We offer five models of granulation machines for your choice: 1-1,5 t/h, 2-2,5 t/h, 2-4 t/h, 4-6 t/h y 6-8 t/h. Satisfy your need for production different size.

What other equipment can I use this machine?

Before the granulation process in the production of fertilizer fertilizers, It is important to crush the material to obtain smaller and uniform particles. The use of crusher It helps break the agglomerations and reduces the size of the particles. This allows greater efficiency in the production of granules and guarantees optimal quality of the final product. After granulation, To improve its marketing and transportation, The granules can be packed with a weighing and packaging machine.

What is the price of the machine?

The price of the machine varies according to the specific model and the production capacity. The price range ranges from 7000 y 25000 US dollars.

What types of services can we offer you?

During the guarantee period specified in the contract, If there are problems in the machinery due to design, manufacturing or materials and are not caused by human error, We offer free repair or replacement services. After the guarantee period, We can provide corresponding services based on the factory price of the equipment.

Get a free price within the 24 hours!