ROTATORY DRUM GRANULATOR

Are you looking for granulation machine for large -scale fertilizer production? Rotary drum granulator can meet your need.

How does the machine work?

Rotary drum granulater is a commonly used equipment in the wet granulation process. When the machine working, The main engine drives the strap and pulley, transmitting the movement to the main axis through a reducer. By connecting fan form installed on the main axis and the large fixed gears in the machine of the machine, They work in the opposite direction. Adding adequate amount of water or steam in machine, The materials get wet and have a completely internally. With certain liquid conditions and the help of the rotating movement of the machine, Materials are manufactured in spherical granules.

What are your advantages?

Compared to other manufacturers, What unique designs does this machine have?

The general structure of the machine is made of Carbon steel High quality, which guarantees that it does not deform with long -term use. We have also performed special treatment inside the machine. Using rubber coatings to avoid corrosion of the material in the machine. Therefore, This granulation team has a better corrosion resistance and a longer shelf life. It is possible that with prolonged use, The materials adhere to the internal wall of the machine. To clean these materials attached to the wall, Our engineers have designed several round holes in the body of the machine. These holes can be beaten to clean the inner wall of the machine.

| Model | Power (kw) | Diameter (mm) | Length (mm) | Installation angle | Rotation speed | Ability (t/h) |

|---|---|---|---|---|---|---|

| SXZGZ-1240 | 5.5 | 1200 | 4000 | 2°-5° | 17 | 1-3 |

| SXZGZ-1560 | 11 | 1500 | 6000 | 2°-5° | 17.5 | 3-5 |

| SXZGZ-1870 | 15 | 1800 | 7000 | 2°-5° | 11.5 | 5-8 |

| SXZGZ-2080 | 18.5 | 2000 | 8000 | 2°-5° | 11 | 8-15 |

| SXZGZ-3210 | 37 | 3200 | 10000 | 2°-5° | 9.5 | 15-30 |

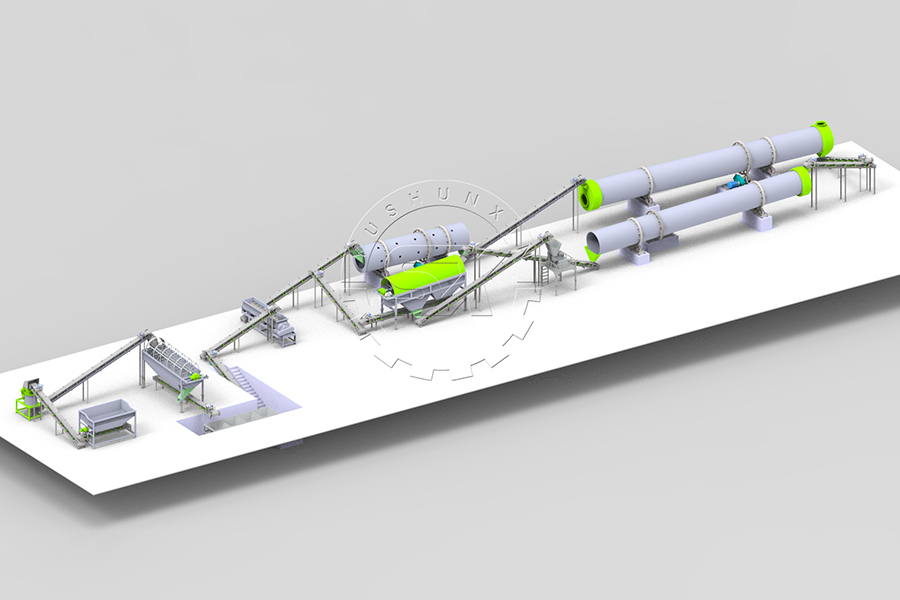

What equipment are necessary for the complete production line with rotating drum?

When planning the construction of the organic fertilizer production line that has as its nucleus the granulation machine with rotating drum, In addition to buying the granulation machine, You must also buy a dispenser, crusher, mixer, screening, dryer, cooler, Coating equipment and Correa transporters. If the moisture of the material is high, You must also buy dehydrating machine To eliminate excess water from the material.

How much does it cost to build full granulation production line with rotating drum?

The cost depends on several factors, Like production capacity, The type and size of the equipment, material prices, inter alia. Therefore, Specific evaluation is needed to obtain precise cost estimation. Such as the Origin, We can offer you special offer for teams. You can establish the granulation machine for low -cost rotating drum.

How much space is needed to build a complete drum line?

What is the size of the particles you manufacture?

In general, This granulation machine can produce granules with size 3-6 millimeters. How does the size of the granules adjust during the granulation process by rotation? We can control it by adjusting the moisture content or controlling the drum rotation speed. The higher the moisture content, greater will be the size of the granules; The lower the moisture content, minor will be the size. The higher the rotation speed, minor will be the size; The lower the rotation speed, greater will be the size. A moisture content of the 20-40% during granulation.

Why do many clients choose our rotary drum granulater?

We have reliable equipment and a professional service team that can meet all the needs it may have in fertilizer production.

Hopefully collaborate with you!

Get a free price within the 24 hours!