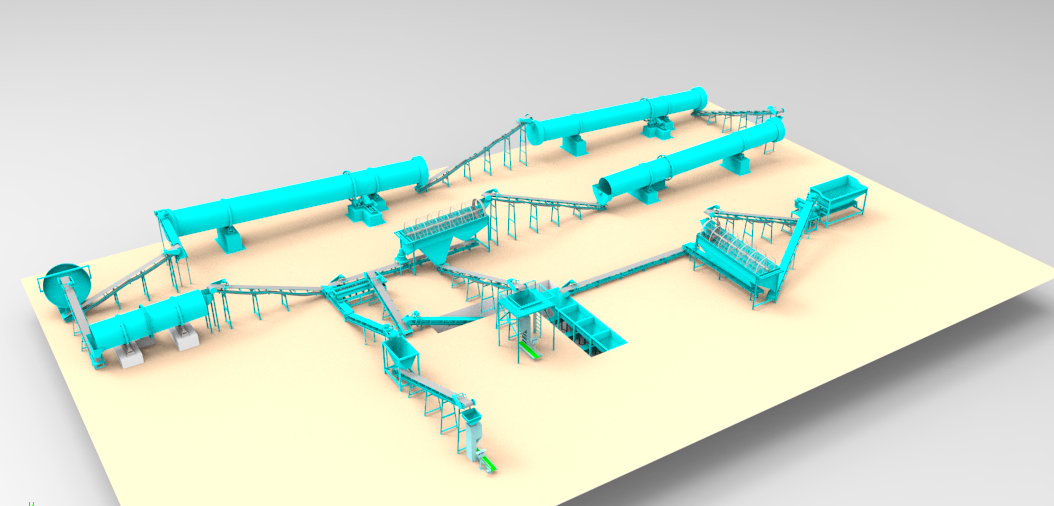

The full production line of machinery

The full production line of machinery

With the rapid development of modern agriculture, The demand for organic fertilizers is increasing. Although traditional chemical fertilizers can quickly increase crops, its prolonged use can have adverse effects on the soil and the environment. By introducing a complete mechanical equipment production line to convert chicken and cow manure into organic fertilizers, Not only can the waste use value be improved, It can also provide high quality organic fertilizers for agricultural production and promote the development of organic farming.

Summary of the project

This project aims to design and implement a complete mechanical equipment production line dedicated to processing Chicken manure and cow to produce efficient and environmental organic fertilizers. The production line includes the treatment of raw materials, fermentation, trituration, mix, granulation, Drying, cooling, screening and packaged, achieving automated and efficient production.

How to configure a complete organic fertilizer production line?

To obtain high quality organic fertilizers, It is necessary to perform a complete fermentation of the manure. This process not only eliminates harmful bacteria and pathogens, but also transforms organic matter into nutrients that plants can easily absorb, thus improving the efficacy and safety of organic fertilizer. To ensure that the fermentation process is efficient and stable, It is essential to use High efficacy fermentation equipment.

Among the fermentation equipment available, The organic fertilizer fermentation tank and the channel compost turning.

Organic fertilizer fermentation tank

The organic fertilizer fermentation tank It is a closed fermentation team, generally manufactured with stainless steel or other corrosion resistant materials. Its main features and advantages include:

Large -scale treatment:

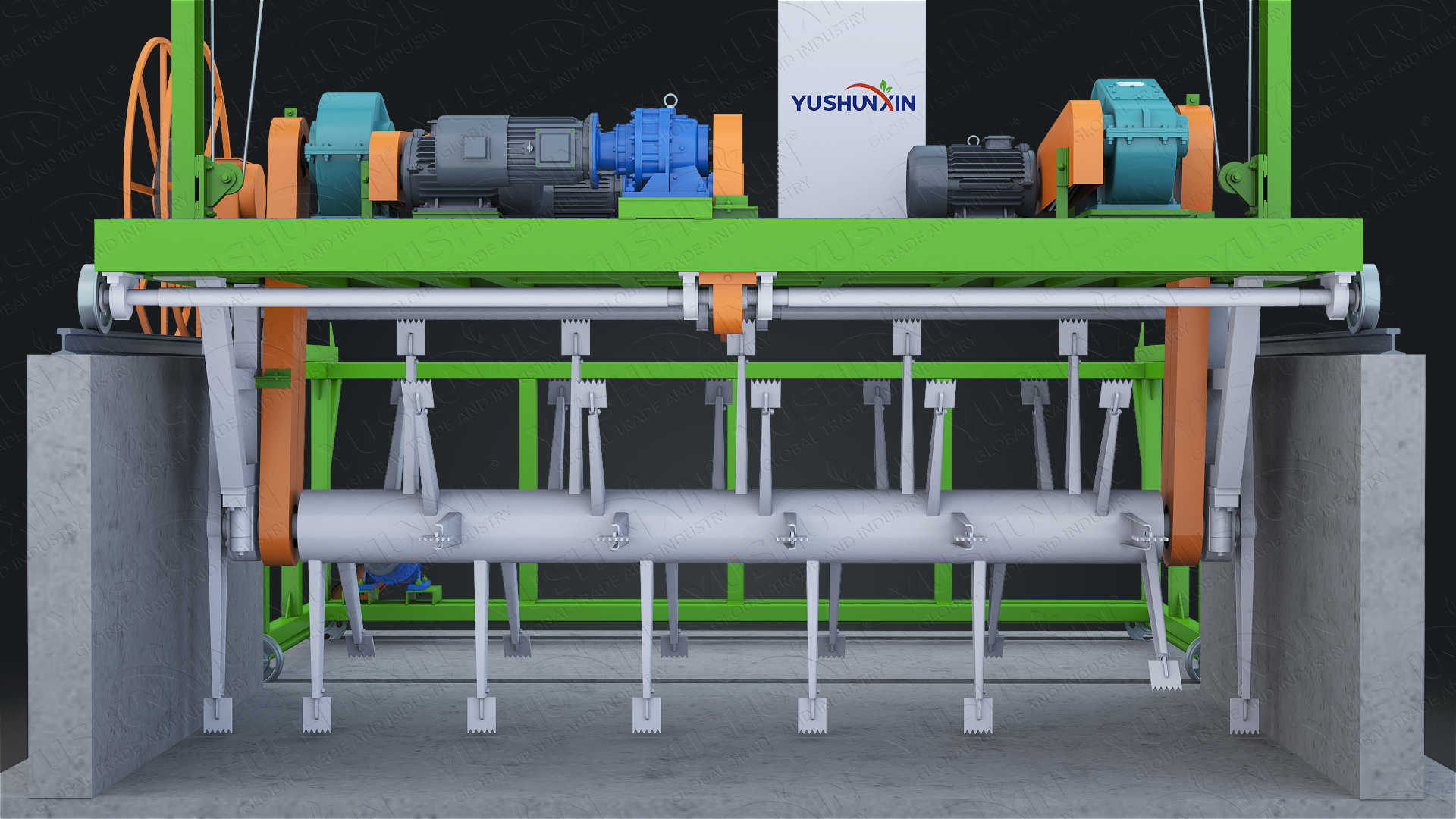

The channel compost turner It is suitable for treating large amounts of organic waste, especially in medium and large size farms or organic fertilizer production companies.

Channel type compost turner technology

Channel type compost turner

The channel compost turner is an open fermentation team, generally used together with fermentation channels. Its main features and advantages include:

Pumping uniform:

Through the mechanical arm flip action, Materials mix and air completely, accelerating the decomposition and fermentation of organic matter.

Lower cost

Compared to the fermentation tank, Initial investment and maintenance costs of the channel compost turning, being cheaper.

Simple operation:

The team It is easy to operate and maintain, being able to complete the fermentation and flip of large amounts of raw material in a short time.

Combined use

How to choose the crushing equipment for organic fertilizer?

In the production of organic fertilizer, The process of trituration es crucial. The smaller the particles, More fluid will be the posterior granulation process and the higher the product quality. This is because smaller particles can be mixed more uniformly, which promotes the homogeneity and stability of organic fertilizer, improving efficiency in the use of nutrients. Besides, Fine particles can increase the efficiency of the granulation machine, reducing the fracture and waste of particles.

New vertical crushers

The new vertical crusher It is able to crush organic materials in extremely fine particles, which not only improves the granulation effect, It also significantly increases the efficiency of production in general.

Organic fertilizer classification

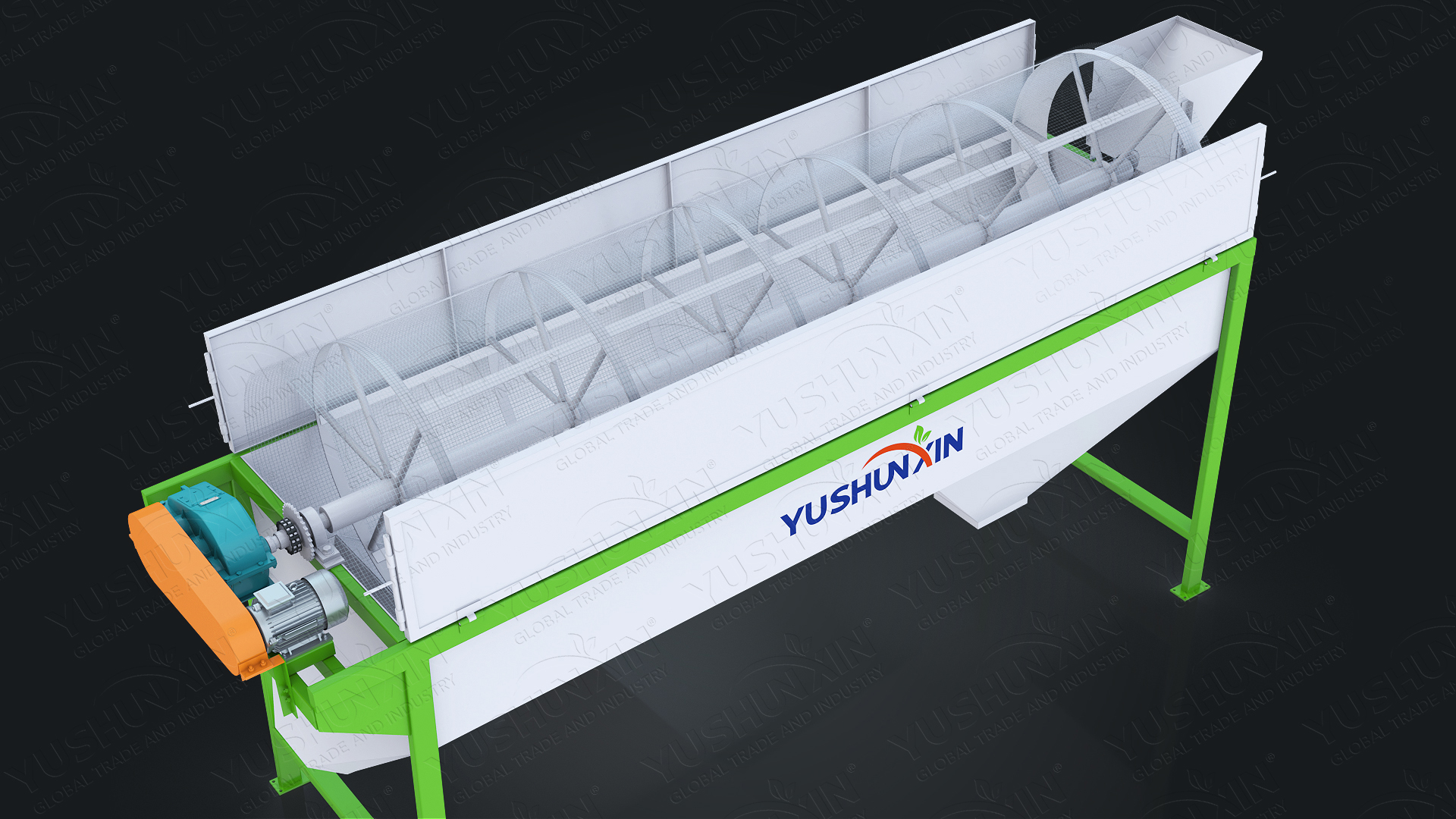

After crushing, It is necessary to use a drum screen to classify the composting of chicken and cow manure completed. The drum screen classifies the materials by drum rotation, efficiently separating large particles and non -satisfied materials, thus guaranteeing the quality of the final product. Drum screening design is simple but efficient. It consists of a tamiz inclined with meshes of different sizes inside. The materials roll inside the rotating drum and are classified by screening action, separating large particles and unredeemed impurities that are expelled out of the drum.

Organic fertilizer formulation

The organic fertilizer of a single component, although it has some nutritional value and ability to improve soil structure, often cannot completely meet the diverse nutritional needs of crops. Therefore, To improve the integral effect of organic fertilizer and its competitiveness in the market, It is necessary to add some other elements to the basic organic fertilizer.

With an automatic dosing machine, Several necessary elements in specific proportions in the organic fertilizer can be accurately mixed, guaranteeing that each portion of fertilizer has a uniform and consistent composition. The automatic dosing machine uses advanced sensors and a control system that can monitor and adjust in real time the amount of each added element, avoiding errors and lack of uniformity that can cause manual dosage. This way, Not only is the quality and consistency of fertilizer improve, It also considerably increases production efficiency and labor costs are reduced.

About the team

Organic fertilizer mixture

After completing dosing, The various elements need to be mixed completely and homogeneously to ensure that the final product has a uniform quality and composition. In this process, The choice of appropriate mixing equipment is especially important. Double axis horizontal mixer is a equipment that stands out in this area and is widely used in organic fertilizer.

Energy Generation

Quality Index

Product Quality Index

Energy Generation

Granulation of organic fertilizer

Once the organic fertilizer mixture is completed, You can proceed to the granulation stage. This step implies converting, through mechanical processing, the raw materials of organic fertilizer already mixed homogeneously in granulated products to facilitate its storage, transport and use. In the organic fertilizer production process, The choice of granulation technology is crucial, since it directly affects the quality and performance of the final product. The rotary drum granulator and the disc granulator are common equipment in the granulation process, each with unique characteristics and advantages.

Energy Generation

Quality Index

Product Quality Index

Energy Generation

Considerations for the choice of the team

How to quickly dry and cool organic fertilizer granules?

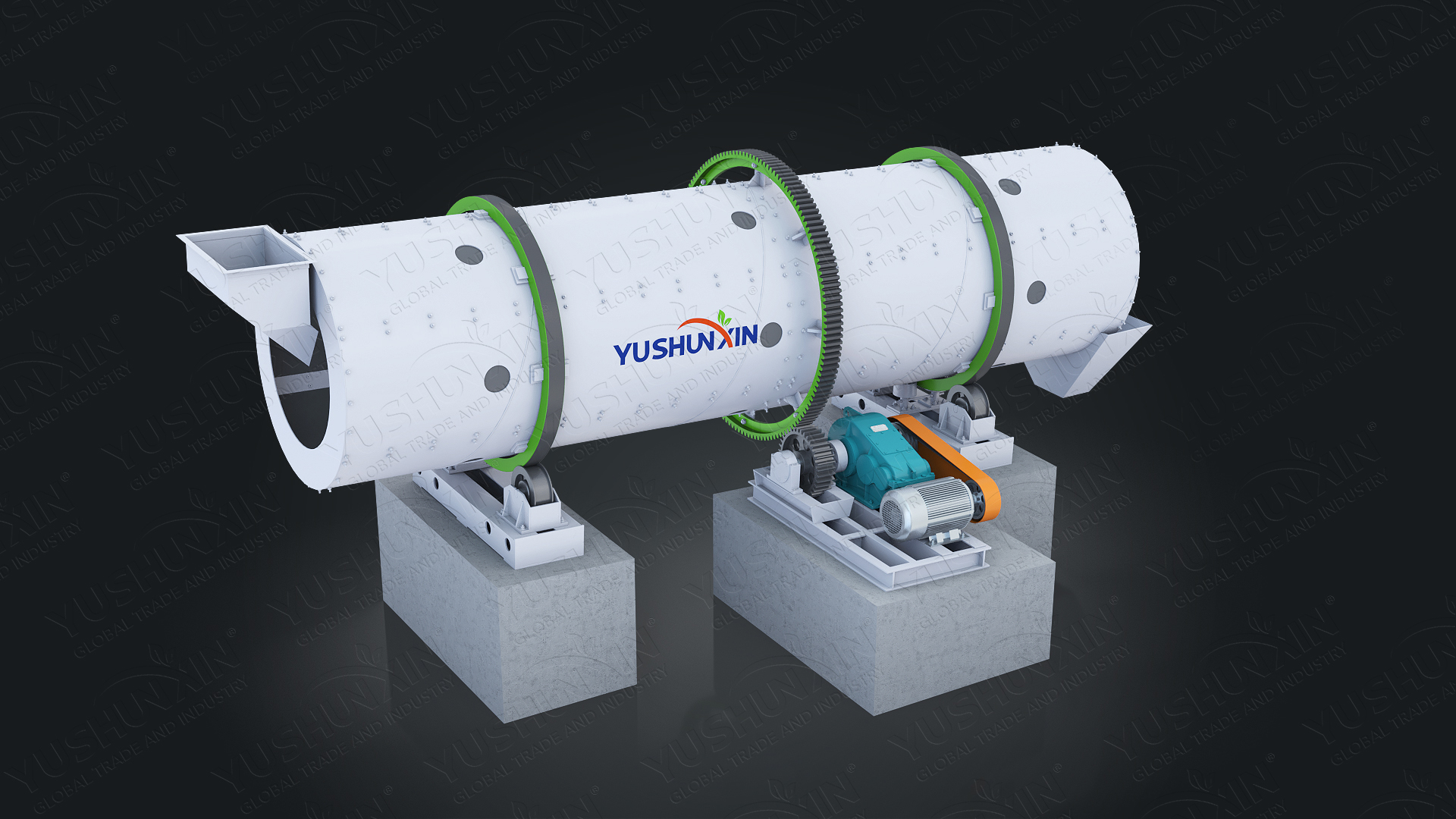

Because both the rotary drum granulater and the disc granulator use the wet granulation method, Which means that during the granulation process a certain amount of water or liquid must be added so that the material gradually form granules under mechanical action. However, The newly formed organic fertilizer granules usually contain a high moisture content and must undergo a subsequent drying and cooling treatment to guarantee the quality and stability of the final product. In this process, The rotary dryer and rotary cooler are common and essential equipment.

Energy Generation

Quality Index

Product Quality Index

Energy Generation

Because both the rotary drum granulater and the disc granulator use the wet granulation method, Which means that during the granulation process a certain amount of water or liquid must be added so that the material gradually form granules under mechanical action. However, The newly formed organic fertilizer granules usually contain a high moisture content and must undergo a subsequent drying and cooling treatment to guarantee the quality and stability of the final product. In this process, The rotary dryer and rotary cooler are common and essential equipment.

1. Fast cooling: The rotary cooler, by internal rotation and air flow, Quickly cool high temperature granules to ambient temperature, preventing granules from deteriorating or damaging due to high temperature.

The rotary cooler Organic fertilizers

The rotary cooler Organic fertilizers

After the drying process, The temperature of the granules is usually high. If they are packed or stored directly, Granuli can deform or suffer greater evaporation of moisture. Therefore, cooling treatment is necessary, And the rotary cooler is indispensable in this process. Next, The characteristics and functions of the rotary cooler are presented:

2. Uniform cooling: The internal design of the team is reasonable, which allows the material to be distributed and cool evenly during the cooling process, ensuring that each granulus decreases its temperature uniformly, improving the consistency and stability of the product.

3. Energy efficiency and respect for the environment: Rotary cooler fully uses the air convection during the cooling process, No need for additional cooling means, reducing energy consumption and operating costs, and minimizing the environmental impact.

4. Automatic control: Equipped with an automatic temperature monitoring and control system, You can automatically adjust the intensity of cooling according to the temperature changes of the granules, guaranteeing the best cooling effect.

Get a free price within the 24 hours!