What are its advantages of the composting turner?

- The pouring with a caterpillar can be very useful to accelerate the voltage process and ensure that the entire fertilizer is mixed and exposed properly to the air and moisture. When using the turner with caterpillar, It is possible to significantly accelerate the decomposition and maturation of organic fertilizer, thus obtaining a final high quality product.

- The turner con caterpillar It also helps introduce fresh air into the fertilizer, what is beneficial for the growth of aerobic microorganisms, which are necessary for the decomposition and maturation of organic matter.

- Compared to traditional manual turning methods, The turner with a caterpillar can mix organic materials more completely, fast and uniform, making sure that each party receives enough oxygen supply.

What are the main principles?

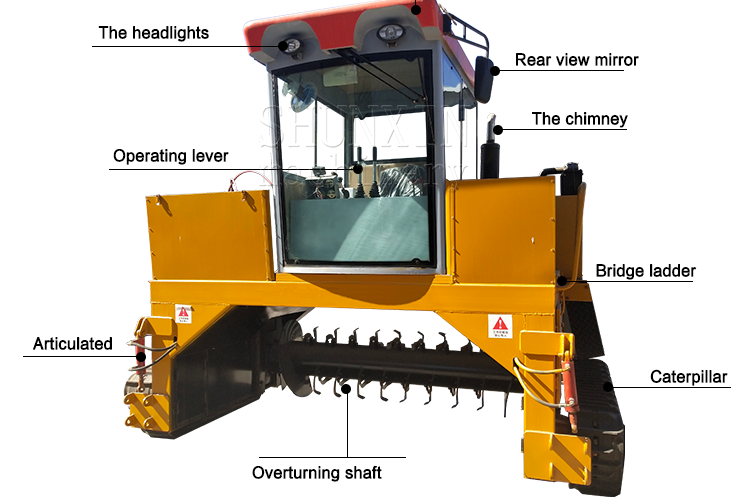

When the turner with a caterpillar is in operation, Mixing tooth underneath and mix the materials effectively. At the same time, Mixing teeth are adjustable. Can be adjusted by small presses hydraulic on both sides of the machine according to the height of the material.

What is your processing capacity?

- According to the model, Its flip width varies between 2.4 y 3.0 metros, The turning height is 0.6 a 1.5 metros. The average speed of movement is 6 a 10 meters per hour. The hour -time processing capacity ranges from 500 y 1500 cubic meters. In general, It is recommended that the optimal distance between the materials be 0.8 a 1 metro.

| Model | SXLDF-2400 | SXLDF-2600 | SXLDF-2800 | SXLDF-3000 |

|---|---|---|---|---|

| Width of working (mm) | 2400 | 2600 | 2800 | 3000 |

| Working height (mm) | 600-1000 | 1000-1300 | 1100-1400 | 1300-1500 |

| Both space (mm) | 800-1000 | 800-1000 | 800-1000 | 800-1000 |

| Maximum diameter of material particles (mm) | 250 | 250 | 250 | 250 |

| Podencia | 85 | 116 | 123 | 156 |

| Teeth diameter (mm) | 400 | 500 | 500 | 500 |

| Speed of working (m/my) | 6-10 | 6-10 | 6-10 | 6-10 |

| Ability (m³/h) | 500-700 | 1000-1200 | 1100-1300 | 1500 |

What is the price of the Volteadora with caterpillar?

- The price of the turner with a caterpillar is between 10000-70000 US dollars.

- In general, Most customers who process organic fertilizer equip a crusher, A screen and an automatic packaging machine for use. After finishing fermentation, Materials are crushed, They are screening and then packed to sell organic powder fertilizer. If you want to make organic fertilizer even more granules, You can use a granulation machine together with the crusher, The screening and the automatic packaging machine. Granulation can further increase the added value of organic fertilizer and is very convenient for storage and transport and long storage.

If you want to get more details and specific budget, Do not hesitate to contact us. We will be happy to provide more information and help you with your organic fertilizer production needs.

Get a free price within the 24 hours!